جراندشاين صب البلاستيك Range and Advantage

The plastic injection molding range of Grandshine comprises a vast spectrum of applications, from industrial components and consumer goods to medical devices. These versatile molding capabilities of Grandshine allow for the production of even complex shapes with precision.

The Grandshine’s commitment to quality and innovation is what sets it apart from competitors. Here’s how choosing Grandshine for your molding requirements will benefit you:

Materials Expertise

Grandshine, a plastic mold manufacturer, offers its services for a wide range of products, from traditional plastics like polyethylene and ABS to advanced materials like nylon and polycarbonate. Their expertise in material selection guarantees that the final products meet the standards and required specifications.

ضبط الجودة

Quality is the top priority of Grandshine. They adopt strict quality control measures so that whatever products leave their facility meets the highest standards. Their dedication to quality yields products that are reliable, durable, and consistent.

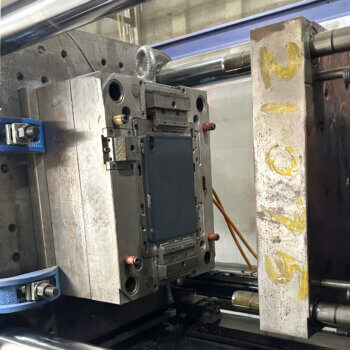

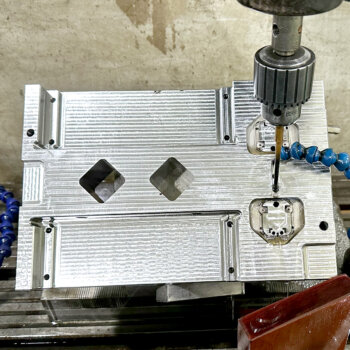

State-of-the-Art Technology

Grandshine employs modern technology and equipment to fulfill its molding needs. A leading plastic mold manufacturer like Grandshine ensures efficiency, high precision, and consistent quality. The technology includes blow molding, injection molding, rotational molding, and more.

Cost Effectiveness

The efficient manufacturing processes and bulk production capabilities of Grandshine translate to cost savings for their clients. Grandshine offers competitive pricing without compromising on quality.

Benefits of Choosing Grandshine for Your Molding الاحتياجات

Customization is crucial to meet the client’s exact requirements for each product. Choosing Grandshine for your molding requirements will benefit you in numerous ways:

النمذجة السريعة

Grandshine is capable of ensuring rapid prototyping, which allows clients to test and refine their product design quickly. Consequently, this speeds up the product development process and decreases the time to market.

Tailored Solutions

Grandshine closely collaborates with its clients to understand their unique requirements. They provide custom-made solutions to meet the exact specifications and design requirements of the product.

Scalability

Whether you are looking for a small-batch or high-volume production, Grandshine has the scalability to meet your specific requirements. This flexibility is helpful for startups as well as established businesses.

Design Assistance

The Grandshine team is based on experienced engineers and designers who help provide valuable insights and recommendations to improve product design during the manufacturing process.

Grandshine’s Plastic Injection Molding Customization Capability

Grandshine’s expertise in the customization of the molds is based on its adaptable and versatile approach. Grandshine is here to fulfill your wide range of customization needs, including:

Color Customization

Grandshine offers a range of color options depending on your brand and design requirements. Grandshine has got you covered whether you need vibrant hues or subtle shades.

Texture and Finish

Custom texture and finish options help you get the desired look of your product. Grandshine can accommodate your preferences, whether you need a matte, glossy, or textured surface.

Overmolding

Grandshine’s overmolding expertise guarantees a strong and durable connection if your product design needs the bonding of two different materials.

إدخال القالب

For products that need additional components or inserts, Grandshine’s insert molding capability ensures a secure and seamless integration of these elements.

Successful صب البلاستيك Projects by الحفيد

Numerous successful molding projects guarantee Grandshine’s dedication to innovation, quality, and customer satisfaction. Here are some noteworthy cases of Grandshine’s success:

Medical Device Housings

Grandshine is an expert in manufacturing high-precision medical device housings that play an essential role in the healthcare industry, ensuring the reliability and safety of medical equipment.

الالكترونيات الاستهلاكية

Grandshine is a trusted partner for many consumer electronic brands, producing aesthetically pleasing and durable casings and components of different devices.

Automotive Components

Grandshine has provided custom solutions for leading automotive manufacturers. Grandshine produces precision-engineered components that meet the industry standards when it comes to performance and safety.

Sustainable Packaging

Grandshine is involved in sustainable initiatives and offers eco-friendly solutions to reduce environmental impact and align with today’s sustainability goals.

Contact Grandshine Today

Give us a call at Grandshine today if you want to benefit from the custom plastic molding or need high-quality plastic components. Our experienced team of engineers and designers will collaborate closely with you to give life to your ideas. At Grandshine, we ensure your product meets high-quality standards while we keep them cost-effective. We are dedicated to quality, innovation, and our client’s satisfaction.Email your custom mold requirement at kaiwin@grashine.com