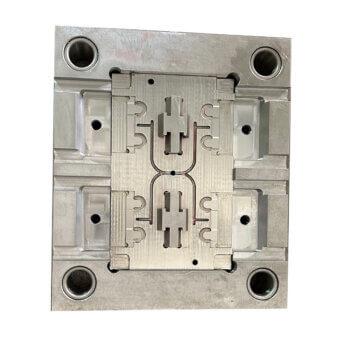

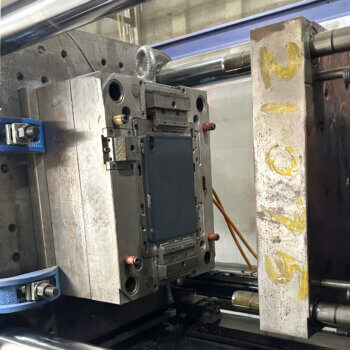

제품 폴리프로필렌으로 성형

폴리프로필렌 사출 성형은 그 뛰어난 특성으로 인해 다양한 제품을 생산하는 데 널리 사용됩니다.

일반적인 응용 분야는 다음과 같습니다.

패키지

이 소재는 일반적으로 용기, 뚜껑, 병 등의 포장재 생산에 사용됩니다. 폴리프로필렌은 습기, 화학물질, 충격에 대한 뛰어난 내구성으로 인해 내용물을 보호하는 데 가장 적합한 선택으로 널리 알려져 있습니다.

소비재

가전제품, 장난감, 가구 등 다양한 소비재는 폴리프로필렌 제조로 생산됩니다. 폴리프로필렌은 색칠이 쉬운데, 이는 미적인 감각이 필요한 품목에 매우 중요합니다.

자동차 부품

폴리프로필렌 제조는 대시보드, 범퍼, 도어 패널과 같은 다양한 자동차 내부 및 외부 구성품을 제조하는 데 도움이 됩니다. 폴리프로필렌은 내구성과 가벼운 무게 덕분에 이런 용도에 큰 이점을 제공합니다.

의료 장비

폴리프로필렌의 생체적합성, 살균적합성, 내화학성은 의료기기 및 장비 제조에 도움이 됩니다. 이를 통해 제품의 안전성과 효과가 보장됩니다.

산업용 응용 분야

산업계에서는 폴리프로필렌 사출 성형을 사용하여 부속품, 밸브, 장비 하우징 등의 부품을 만듭니다. 폴리프로필렌은 내화학성, 내열성, 내습성이 뛰어나 신뢰할 수 있는 선택입니다.

의 특성 폴리프로필렌 성형

폴리프로필렌 사출 성형은 독특한 특성을 가지고 있어 인기가 많습니다. 주요 기능은 다음과 같습니다.

내화학성

폴리프로필렌은 의료 및 화학 가공을 포함한 다양한 산업에 필수적인 광범위한 화학 물질에 대한 뛰어난 내성을 제공합니다.

높은 충격 강도

재료는 변형이나 파손 없이 큰 충격을 견딜 수 있으므로 제조된 제품의 내구성.

비용 효율성

폴리프로필렌은 비용 대비 효과적인 제품이기 때문에 생산 비용을 최적화하고자 하는 제조업체에게 가장 좋은 선택입니다.

재활용성

재활용이 가능한 소재인 폴리프로필렌은 지속 가능하고 환경 친화적인 제조 관행에 대한 증가하는 수요를 충족합니다.

내열성

폴리프로필렌은 특성을 잃거나 변형시키지 않고 고온을 견딜 수 있어 내열 제품에 적합한 선택입니다.

빛

폴리프로필렌은 가벼운 소재이기 때문에 자동차 산업과 같이 무게 감소가 요구되는 분야에 적합합니다.

그랜드샤인의 폴리프로필렌 사출 성형을 위한 파트너 전략

그랜드샤인은 제조 부문으로서 회사와 협력하는 전략을 개발했습니다. 이 팀은 고객과 협력하여 시장을 확대하고 양측 모두에게 이익이 되는 상황을 만들어냅니다.

이러한 파트너십을 통해 귀하에게 얻을 수 있는 이점은 다음과 같습니다.

생산을 단순화하세요

Grandshine에 제조를 아웃소싱하면 전문가가 생산을 관리하는 동안 기업은 판매와 시장 확대에 집중할 수 있습니다.

제조 전문성을 얻으세요

귀사의 공장인 그랜드샤인은 폴리프로필렌 제조 분야에서 수년간의 경험과 전문성을 보유하고 있어 귀사 제품의 고품질 생산을 보장합니다.

시장 확장

그랜드샤인의 현지 영업팀은 새로운 시장과 고객에게 다가가는 데 도움을 주어 귀하의 사업이 성장하도록 도울 수 있습니다.

비용을 절감하다

Grandshine의 제조 역량을 활용하면 비용 절감을 달성할 수 있습니다. 따라서 생산성과 확립된 인프라를 활용할 수 있습니다.

위험 완화

Grandshine과 협력하게 되면 제조와 관련된 책임과 위험이 줄어듭니다. 즉, Grandshine은 귀사의 제작 과제에 대한 믿음직스럽고 신뢰할 수 있는 파트너가 될 것입니다.

Grandshine은 어떻게 합리적인 가격을 제공할 수 있습니까? 금형 제조 물가?

그랜드샤인에서는 높은 품질 기준을 고수하는 동시에 고객의 시장 지위에 맞춰 폴리프로필렌 제조 가격을 제공합니다. 우리는 귀사의 성공이 경쟁력 있는 가격에 달려 있다는 것을 알고 있습니다. 즉, 우리는 귀하의 상황에 맞춰 맞춤형 제안을 제공하여 수익성 있는 파트너십을 보장합니다.

우리는 비용 효율성이 품질에 대한 타협을 의미하지 않는다고 믿습니다. 당사의 엄격한 품질 관리 조치를 통해 모든 제품이 고객의 요구 사항과 기준을 충족하도록 보장합니다. 우리는 장기적이고 지속 가능한 파트너십을 믿습니다. Grandshine과 협력하면 귀하의 성공을 위해 최선을 다하는 제조업체와 협력하게 됩니다.

시장 중심적 접근 방식

그랜드샤인에서는 시장 역학의 중요성을 알고 있습니다. 따라서 가격은 귀하의 시장 지위에 따라 달라집니다. 즉, 우리는 귀사가 귀하의 산업 분야에서 경쟁력을 유지할 수 있도록 도와드립니다.

투명한 협업

당사의 가격 모델은 투명하고, 개방적이며, 협력적인 토론을 기반으로 합니다. 저희는 귀하의 예산과 목표에 맞는 가격 구조를 찾을 수 있도록 모든 단계를 안내해 드리겠습니다.

혁신 중심

그랜드샤인의 최우선 순위는 최신 제조 기술에 지속적으로 투자하는 것입니다. 그렇게 하면 가장 비용 효율적이고 최첨단 폴리프로필렌 성형 솔루션을 얻는 데 도움이 될 수 있습니다.

유연하고 민첩하다

그랜드샤인은 고객의 변화하는 요구와 시장 상황에 맞춰 전략을 조정합니다. 이러한 접근 방식은 파트너십 전체에서 가장 경쟁력 있는 가격을 얻는 데 도움이 될 수 있습니다.

귀하의 성공이 우리의 최우선 순위입니다

그랜드샤인과 협력한다는 것은 여러분의 성공이 곧 저희의 성공이라는 것을 의미합니다. 따라서 저희의 목표는 귀사의 투자에 대한 최고의 가치를 제공하고 귀사의 사업 성장을 돕는 것입니다.

오늘 이메일을 통해 Grandshine에 문의하세요: kaiwin@grashine.com 폴리프로필렌 제조를 위해 헌신하고 오늘날의 경쟁적인 시장에서 귀사의 사업을 새로운 성공의 길로 이끄십시오.