À propos de Grand éclat

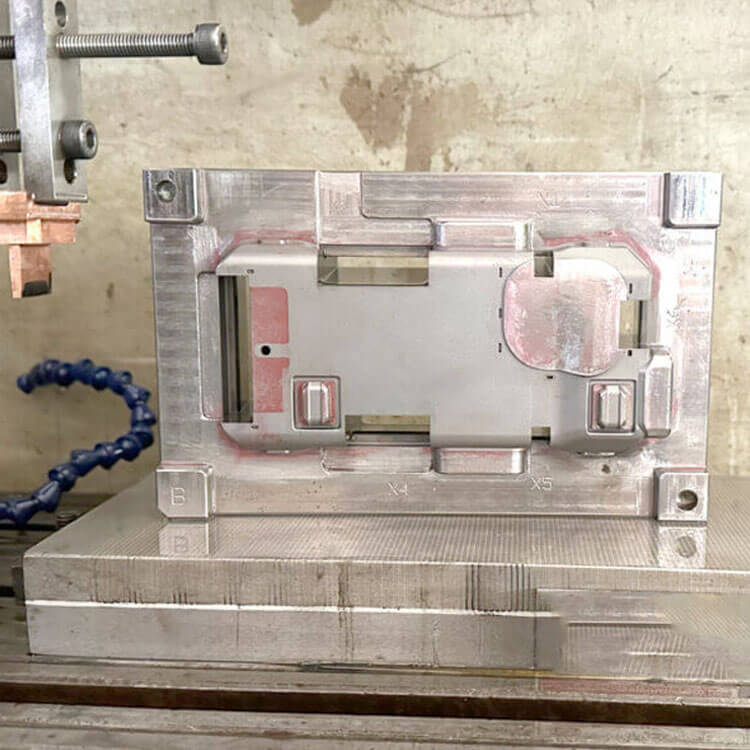

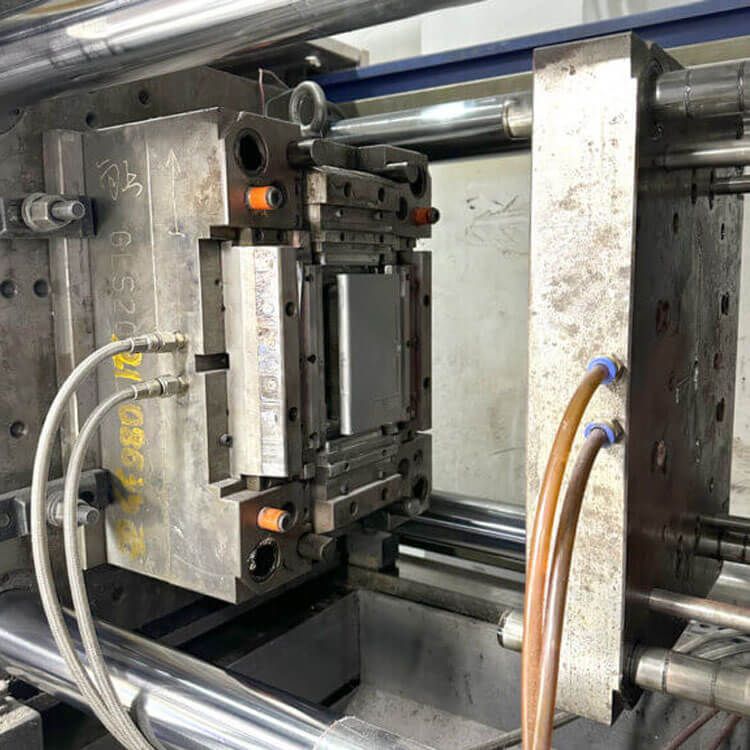

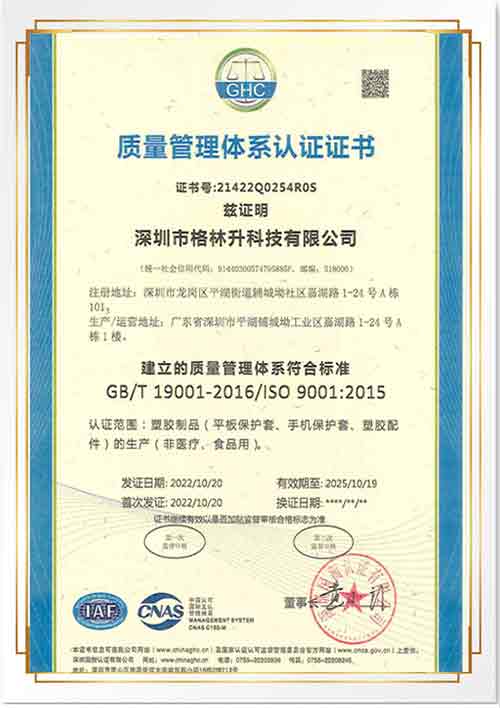

Shenzhen Grandshine Technology Co., Ltd est un leader dans le développement de nouveaux produits et la fabrication de moules plastiques, fort de plus de 20 ans d'expérience. Implantée à Shenzhen (Chine), à Los Angeles (États-Unis) et à Singapour, Grandshine est spécialisée dans la conception de nouveaux produits, les moules d'injection plastique sur mesure, les moules en silicone, les pièces plastiques, le moulage sous pression, les moules d'emboutissage, l'assemblage et la production à grande échelle, offrant une chaîne d'approvisionnement complète et unique.

Au fil des années, notre gamme de produits comprend des accessoires pour téléphones, des accessoires pour tablettes, des accessoires de jeux, des équipements industriels, des produits pour animaux de compagnie et divers articles électroniques grand public.

Nous proposons une solution de fabrication complète, incluant la conception, le prototypage, le moulage, la production en série et l'assemblage final, pour répondre aux exigences de votre chaîne d'approvisionnement. Notre équipe de développement de nouveaux produits vous propose des services de conception industrielle, mécanique, de moules, électronique et de circuits imprimés FPC.