How to Remove Mold Marks?

1. Causes of Mold Marks 1-1 Variations in thickness of the product’s various parts. 1-2 Inadequate internal pressure within the mold. 1-3 Insufficient cooling of the

With bases in Shenzhen China, Los Angeles USA and Singapore. ISO9001:2015 , ISO14001:2015, BSCI B factories audit certificated

We have successfully produced more than 85,000 sets of plastic molds

We have worked with 1000 happy customers

Our products have been successfully exported to 78 countries

We have more than 100 product patents

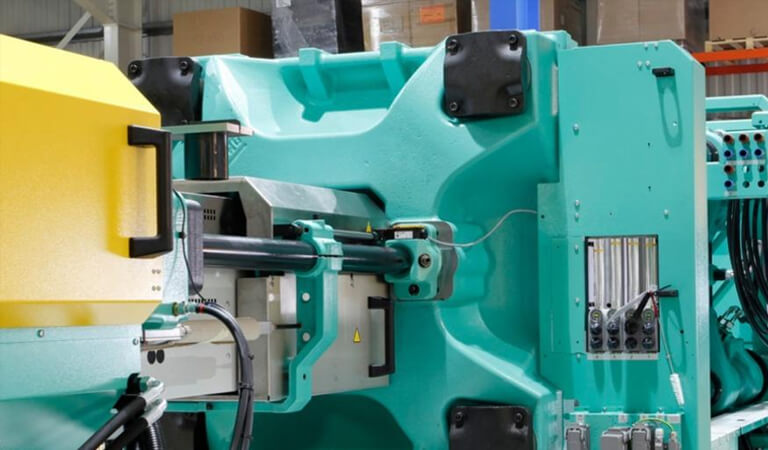

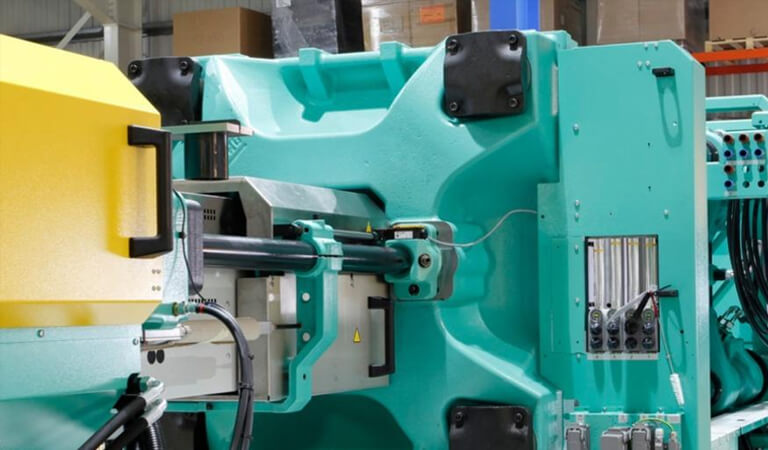

Shenzhen Grandshine Technology Co., Ltd is a leading professional in new product development and plastic mold manufacturer with over 20 years experience. With bases in Shenzhen China, Los Angeles USA as well as Singapore, Grandshine specializes in new product design, custom plastic injection mold, silicone mould, plastic parts, die casting, stamping mould, product assembly and large-scale production, offering comprehensive one-stop supply chain.

Over the years, our products range has encompassed phone accessories, tablet accessories, gaming accessories, industry equipment, pet products and various consumer electronic items.

We provide complete manufacturing solution, include products design, prototype, molding, mass production and final assembly to satisfy your supply chain requirements. With our new product development team, you can get service of industrial design, mechanical design, mold design, electronic design, FPC PCBA design etc.

As leading manufacturer, Grandshine has 20 years experience in manufacturing. Factory has passed ISO9001, ISO14001, BSCI B, SA8000 certification.Our customers include Walmart, Wiko, Mricosoft, Lenovo, Incipio, Case-mate etc .

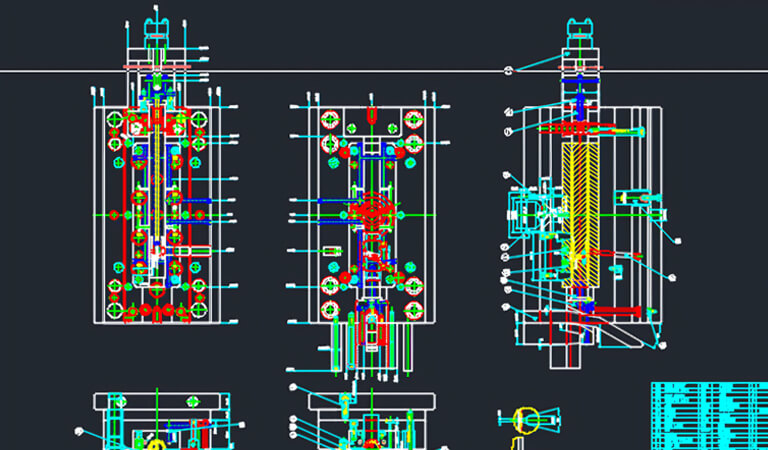

At Grandshine, we understand that many clients may not have professional product designers or lack the expertise in utilizing CAD or Pro E for 3D product design. We offer experienced engineers to create product designs and moulds aligned with manufacturing processes.

Before production, we conduct multiple rounds of rapid rendering and 3D printing prototypes services to ensure our designs meet the highest standards. This allows for cost-effective and small batch sample testing before full-scale production. 3-5 Delivery time.

we select the most suitable plastic molding techniques based on the product's structure and functionality. our offering include precision injection molding, Insert Mold, Co-mold, CNC machining, silicone rubber molding, various molding process

Many clients often facing high MOQ requirements or reluctance from factories to provide logo printing services. We are pleased to offer clients a solution with low MOQ logo printing services, including logo silk printing, logo laser engraving, logo badging, and more.

With production facilities and offices in Shenzhen, Singapore and United States, we provide 7-15 days fast batch production service with 1000 units low MOQ. Say goodbye to the high MOQ requirement of 5000 or 10000 units imposed by other factories for mass production.

We have three standardized product assembly lines, ensuring high-quality assembly services for both plastic components and electronic PCBA products. Whether you require plastic or electronic assemblies, we adhere to ISO 9001 and ISO14001 standards to guarantee quality.

1. Causes of Mold Marks 1-1 Variations in thickness of the product’s various parts. 1-2 Inadequate internal pressure within the mold. 1-3 Insufficient cooling of the

Injection Molding There is no more suitable means of processing TPU than screw-type injection molding machines. Single-threaded, three-stage screws of usual lengths can produce a

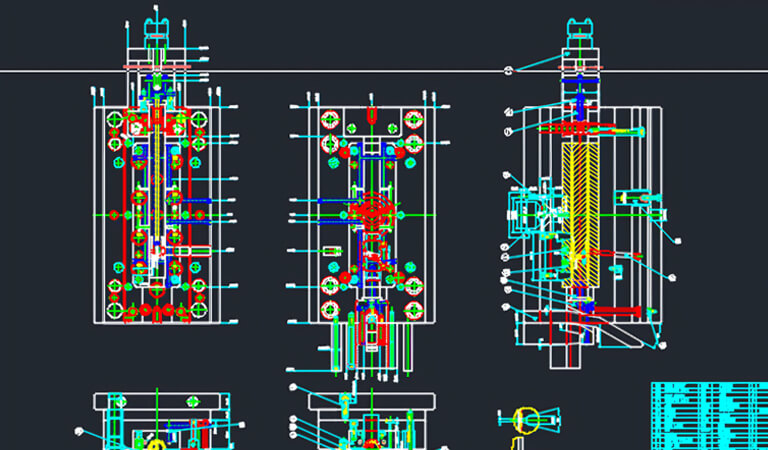

First, accept the mission statement Manufacture of plastic parts of the task book is usually proposed by the part designer, including: after reviewing and signing

1. Causes of Mold Marks 1-1 Variations in thickness of the product’s various parts. 1-2 Inadequate internal pressure within the mold. 1-3 Insufficient cooling of the

Injection Molding There is no more suitable means of processing TPU than screw-type injection molding machines. Single-threaded, three-stage screws of usual lengths can produce a

First, accept the mission statement Manufacture of plastic parts of the task book is usually proposed by the part designer, including: after reviewing and signing

Grandshine is Leading professional in new product development and plastic mold manufacturer with over 20 years experience