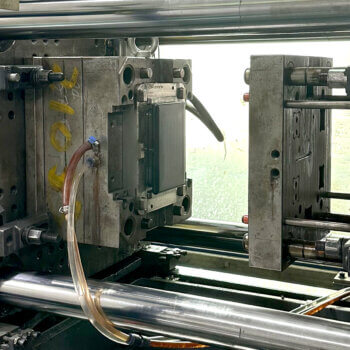

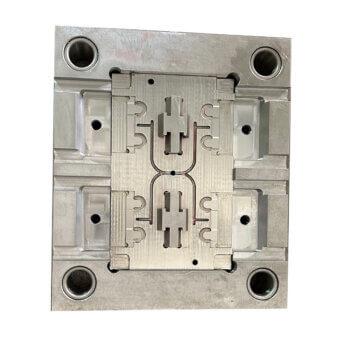

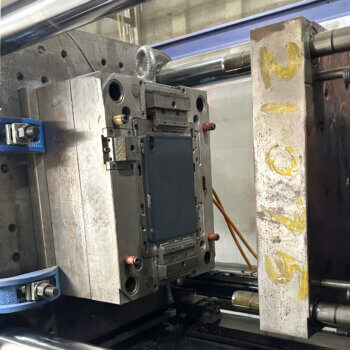

Ferramentas de molde de injeção

Moldagem por injeção de plásticoA moldagem por injeção de plástico é um processo comum para a fabricação de peças e produtos plásticos. O processo consiste na injeção de material plástico aquecido em um molde, permitindo que ele resfrie e endureça, formando a peça ou produto desejado. A moldagem por injeção de plástico é utilizada em diversos setores, incluindo automotivo, eletrônico, bens de consumo, dispositivos médicos, componentes industriais, acessórios para móveis, dispositivos de comunicação, embalagens, equipamentos esportivos e para atividades ao ar livre. |

Fabricantes de moldagem por injeçãoA chave para garantir produtos de alta qualidade é escolher moldes de precisão de alta qualidade para a produção. Ao procurar fabricantes de moldes de injeção, você se deparará com uma variedade de preços oferecidos por diferentes fábricas, com orçamentos de moldes baratos e caros, o que torna a escolha bastante difícil. |

|

|

Moldagem por inserçãoA Grandshine é uma fabricante de moldagem por inserção. Oferecemos moldagem por inserção personalizada para combinar materiais plásticos e metálicos, permitindo a inserção de metal em peças plásticas. Essa tecnologia de moldagem por inserção integra as características de materiais plásticos e metálicos, proporcionando diversas possibilidades de aplicação. Os materiais usados na injeção de moldagem por inserção incluem: Os produtos de moldagem por inserção oferecem vantagens combinadas de maior resistência do produto, processos de montagem simplificados, economia de material e maior flexibilidade de design por meio da integração perfeita de inserções roscadas para moldagem por injeção de plástico. |

Moldagem sobre moldagemA Grandshine tem ampla experiência em sobremoldagem; nossos produtos são amplamente utilizados pelas principais companhias aéreas, como a United Airlines nos Estados Unidos e a Lufthansa na Alemanha. Nossos produtos co-moldados apresentam forte adesão, tendo passado com sucesso em testes rigorosos, incluindo um teste de queda de 10 metros (3 pés) e um teste de violência de tensão. Essas peças sobremoldadas apresentam resistência de 4 graus ao amarelamento e à oxidação. Os produtos de sobremoldagem por injeção da nossa empresa apresentam uma fusão perfeita de dois materiais, imperceptível tanto ao toque quanto a olho nu. Nossa tecnologia de sobremoldagem está no mesmo nível das técnicas de moldagem de precisão do Japão e da Alemanha. A Grandshine oferece moldagem por injeção de sobremoldagem de PC+TPU, sobremoldagem de plástico de PC+Silicone, co-moldagem por injeção de PC+TPE, sobremoldagem de TPU+TPE e outras sobremoldagens de insertos. A Grandshine é a sua melhor escolha em moldes para plástico. |

|

|

Textura de molde de plásticoA textura do molde plástico é o processo de criação de uma textura ou padrão na superfície do molde para que a superfície do produto plástico final tenha uma textura ou padrão específico. Este processo se dá principalmente por meio do uso de um tratamento de superfície especial, como uma ferramenta de limpeza, tratamento químico ou ferramenta de polimento no molde, ou da adição de uma placa de textura para produzir a aparência e o efeito de toque desejados no produto plástico. As opções de textura do molde plástico incluem textura de couro, textura de madeira, textura de cânhamo, textura de malha, textura ondulada, textura de grama e textura perolada. A textura de molde mais comum é a textura fosca mt11010 e o polimento suave. Você pode especificar um número de textura específico ou nos enviar uma amostra da textura do molde plástico desejada para que possamos desenvolver a textura desejada para o molde plástico. |

Fabricante de moldes de plásticoSe você enfrenta problemas frequentes como atraso na entrega do molde, baixa qualidade do molde, falta de precisão nos moldes, vida útil curta do molde, linhas de separação irregulares em componentes plásticos, altas taxas de defeitos no produto, contaminação, coloração irregular, fragilidade das peças moldadas por injeção ou inclusão de materiais reciclados em seus produtos, pode ser hora de procurar um novo fabricante de moldes plásticos. A Grandshine é uma fabricante profissional de moldes plásticos com 20 anos de experiência em moldagem por injeção e moldagem de silicone. Temos o compromisso de fornecer moldes e produtos plásticos de alta qualidade. Nossa promessa inclui o uso de aço totalmente novo para a produção de moldes e matérias-primas frescas para a fabricação dos produtos. Cada projeto conta com uma equipe dedicada de gerenciamento de projetos, supervisionando todas as etapas, desde o design do produto e a produção do molde até a fabricação em larga escala, tudo em conformidade com a norma internacional de gestão da qualidade ISO9001:2015. Isso garante que cada produto que produzimos para você seja de alta precisão e qualidade. Além disso, com escritórios nos Estados Unidos e em Singapura, oferecemos um excelente serviço de pós-venda local. Se você precisa de uma nova fábrica de moldes para plástico, a Grandshine é, sem dúvida, a sua melhor escolha. |

Vídeo sobre fabricação de moldes de injeção de plástico |

Vantagens da fabricação OEM |

| Vida útil do molde 500K Os moldes desenvolvidos pela Grandshine têm uma vida útil de 300.000 a 500.000 ciclos de vida de desenvolvimento de novos produtos, garantindo estabilidade a longo prazo no planejamento e desenvolvimento de produtos. Possuímos certificação ISO9001 e nossos processos de novos produtos receberam as certificações ROHS, CE, FCC e REACH, garantindo produtos de alta qualidade e em conformidade com as normas. |

Prazo de entrega rápido A Grandshine está sempre atenta à sua perspectiva, oferecendo fabricação de moldes de injeção e produtos de alta qualidade dentro do seu orçamento. Além disso, oferecemos um prazo de fabricação de moldes rápido de 15 a 25 dias, permitindo que você lance novos produtos ou atenda às demandas do mercado com agilidade. |

Design preciso A Grandshine designa engenheiros de projeto dedicados para cada projeto, garantindo um gerenciamento abrangente. Antes da fabricação das ferramentas de moldagem por injeção de plástico, fornecemos aos clientes desenhos 3D e 2D para confirmação e oferecemos prototipagem rápida para validação. Esse processo garante que o projeto do molde esteja alinhado aos requisitos e especificações do produto do cliente, atendendo a todos os critérios funcionais, estéticos e de desempenho. |

MOQ baixo Para facilitar a expansão do mercado de clientes e aliviar as restrições de estoque, a Grandshine oferece suporte à produção com uma quantidade mínima de pedido (MOQ) flexível, variando de 500 a 1.000. Essa abordagem permite que os clientes entrem no mercado com confiança e com o mínimo de pressão de estoque. Entre em contato com a Grandshine agora mesmo para dar início ao desenvolvimento dos seus novos produtos! |

A Grandshine é uma fabricante profissional de produtos de moldagem por injeção, oferecendo serviços de injeção de precisão, ferramentas para moldes de injeção de plástico, sobremoldagem para injeção de plástico, insertos para moldagem por injeção de plástico, moldagem de plástico ABS, moldagem por injeção de plástico médico, moldagem por injeção automotiva, moldes para matriz de plástico para PC e outros serviços de moldagem por injeção. Geralmente, utilizamos aço S136 resistente a altas temperaturas e corrosão química como material de molde, após 52 graus de tratamento térmico e tratamento térmico, para garantir que seu molde tenha uma vida útil de 300 mil a 500 mil.

Concentramo-nos em padrões de alta qualidade de produtos e ciclos de produção rápidos, geralmente capazes de desenvolver um conjunto completo de moldes para você em 15 a 25 dias e colocá-lo em produção em massa. Se você precisa de uma quantidade mínima de pedido (MOQ) flexível e deseja escolher um fabricante de moldagem por injeção de plástico com certificação ISO9001, ISO14001 e BSCI, a Grandshine é a melhor escolha para você.