Let’s dig a little deeper into the world of Grandshine and explore how they transform concepts into reality.

Grandshine’s Diverse Range of Large Plastic Mold Products

Grandshine possesses a diverse portfolio of large plastic mold products, including medical devices plastic parts, home application plastic parts, and car plastic parts. Our team has expertise across multiple industries, which makes us a one-stop solution for all your plastic component requirements.

Fortunately, Grandshine has got you covered whether you need cutting-edge medical device components, precision-engineered parts for the automotive industry, or innovative plastic solutions for home applications. Over the years, their product range has included tablet accessories, gaming accessories, IOT device accessories, as well as consumer electronic items. Grand éclat has already served its famous customers, including Case-mate, Incipio, Lenovo, Microsoft, Walmart, and Wiko.

You will get product design, prototype, molding, mass production, and final assembly one-stop manufacturing solution, all through Grandshine. Grandshine has set up branches in China and Malaysia for your convenience. However, our local warehouses are found in numerous countries, including the UK, USA, Spain, Germany, Vietnam, Australia, Ghana, Nigeria, Philippines, Tanzania, etc., and you are always welcome to visit us.

Commitment to Quality: ISO14001:2015 and ISO9001:2015 Certification

Quality is an essential requirement of Grandshine’s operations. We stick to ISO14001:2015 environment management system and ISO9001:2015 quality management system, which shows our dedication to environmental responsibility as well as customer satisfaction. These certifications show Grandshine’s commitment to the highest industry standards and ensure every product or service they provide meets customer satisfaction.

Grandshine prefers to use environmentally friendly and recyclable thermoplastic materials. Their recycling programs ensure the proper management of excess materials and scrap. These certifications prove that we are committed to reducing the environmental impact of our processes.

Grandshine’s Comprehensive Large Injection Molding Services

Grandshine’s services include the entire lifecycle of production of the plastic component. Grandshine’s comprehensive set of services includes every aspect of large-part injection molding so that your projects are brought to life smoothly and with utmost precision.

Here is a breakdown of our large injection molding services:

Conception de moules

Grandshine, a large plastic mold maker, has expertise at every step, from product design analysis to Design for Manufacturing (DFM) evaluation, mold structure design, and product material selection. They use advanced technologies like CAD or CAM to create 3D models that provide the basis for your project.

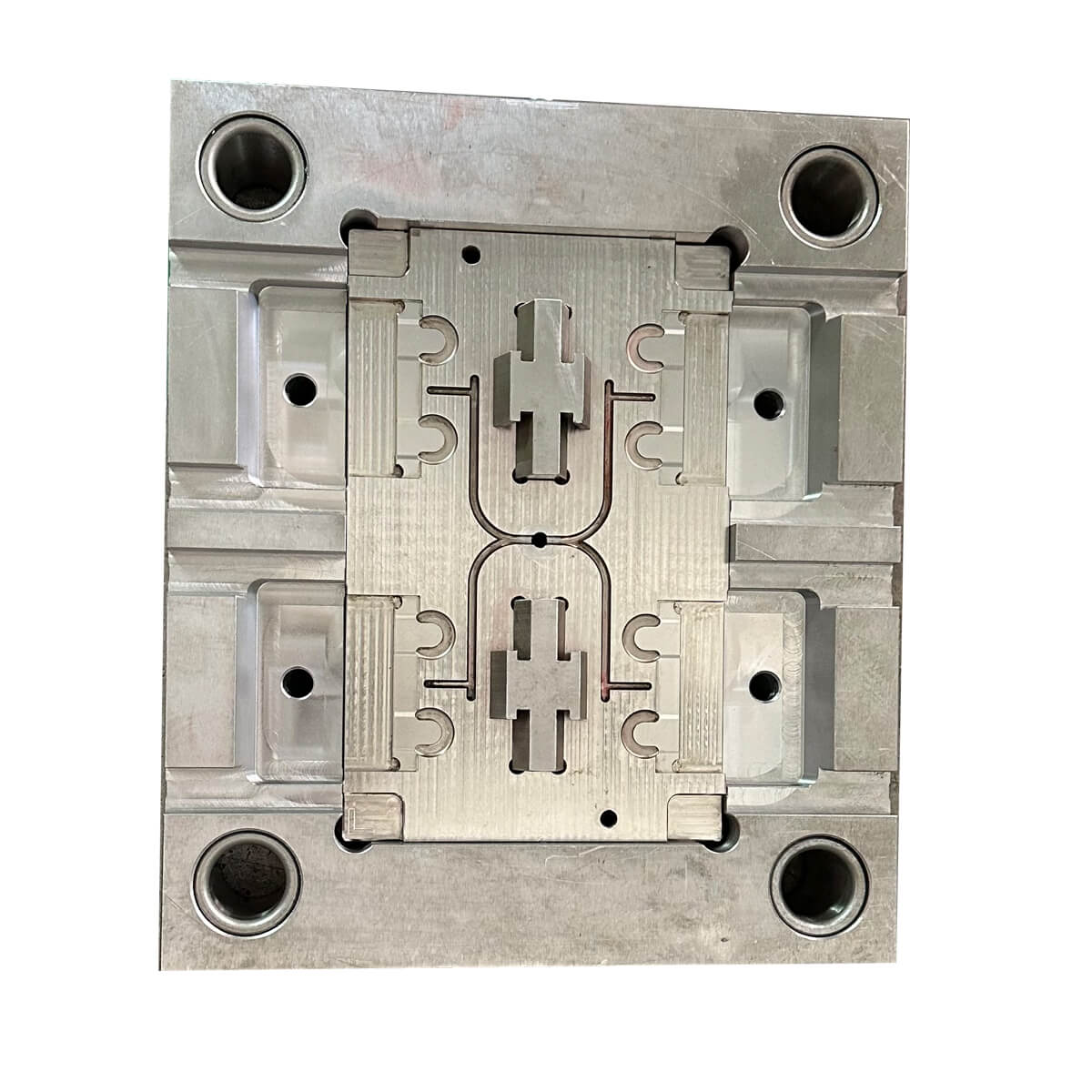

Mold Manufacturing

The heart of large-part injection molding lies in the production of precision injection and hardware molds. At Grandshine, our experienced team manufactures injection and hardware molds according to your design specifications, ensuring efficiency and precision in the production process.

Selection of Raw Materials

Our experienced team at Grandshine carefully chooses the ideal plastic raw materials according to your project demand. When it comes to raw materials, we offer numerous options, including (Polycarbonate) PC, (Thermoplastic Polyurethane) TPU, (Thermoplastic Elastomer) TPE, (Acrylonitrile Butadiene Styrene) ABS, (Polypropylene) PP, (Polyoxymethylene) POM, and many more. This ensures that your plastic parts are perfectly chosen for the right purpose.

Mouler Trial

Grandshine conducts meticulous mold trials and testing to ensure dimensional accuracy and optimal performance before moving toward full-scale production. Grandshine provides T0, T1, and T2 samples for customer evaluation to ensure the product’s smooth transition to production.

Maintenance and Repair

A large plastic mold maker like Grandshine conducts regular maintenance and repair to ensure long-term mold performance. This maintenance includes cleaning, lubrication, and the replacement of worn parts so that the molds remain in optimal condition.

Production Process Support

Grandshine provides a wide range of production process support services, such as pattern printing, logo screen printing, logo radium carving, water transfer, thermal transfer, spraying, and more. These value-added processes improve the functional aspects of your components as well as enhance the aesthetic.

Mold Improvement

Our customer feedback and requirements matter to us. This feedback might include issues and challenges our customers have experienced with the molds, such as quality concerns, part defects, changes in product requirements, and production inefficiencies. That said, we pay more attention to mold improvements to enhance efficiency, longevity, and performance.

Quality Control

Grandshine’s stringent quality control measures are a promise that all manufactured products meet requirements and specifications.

In addition to being capable of providing large injection molding services, they have their own laboratory and can conduct various tests. These tests include salt spray tests, drop tests, environmental protection tests, and high and low-temperature tests. All products manufactured at Grandshine pass certifications like FCC, UKCA, CE, RoHS, and Reach.

Technical Support

Grandshine offers technical support to help resolve mold and production-related issues, having a professional engineering team at its side.

After Sales Service

Fortunately, Grandshine has built a local after-sales service system in each country to address customer concerns. This system also provides troubleshooting aid and parts replacement as per the requirements.

Why Choose Grand éclat?

Being a large plastic mold maker, here is what makes Grandshine a perfect option in the manufacturing industry:

Evaluation and Analysis

The engineering and technical team of Grandshine evaluates the customer feedback and performs analysis on the existing molds. They do a detailed assessment to identify areas that need improvement. This assessment is based on a comprehensive analysis of the mold’s design, material compatibility, and performance during the large moulage par injection process.

Quality Enhancement

One of the primary goals of Grandshine is to satisfy the customer needs, whether it includes mold improvement. Mold improvement is a part of large-part injection molding and is done to improve the quality of the manufactured parts.

Grandshine focuses on refining the mold to limit defects and variations in the final products. Consequently, doing this leads to cost savings and improved consistency in the manufacturing process.

Customized Solutions

Grandshine offers customized solutions to address the specific issues and concerns of their customers. These customized solutions include modifications to the mold design, adjustments to the large injection molding process parameters, or changes in the choice of materials.

Mold’s Life Extension

Grandshine is a perfect choice for customers looking to prolong the life of expensive large-part injection molds. Besides, it’s a cost-effective strategy and extends the operational life of the molds.

Efficiency and Productivity

Grand éclat also promises to pay attention to improving the efficiency and productivity of the large-part injection molding process. This includes increasing the overall yield of acceptable parts, reducing scrap rates, as well as optimizing cycle times.

Performance Enhancement

Grandshine’s team also focuses on improving the overall performance of the molds so that they operate at their maximum potential. This includes refining features like gating, venting, and cooling systems.

Testing and Validation

Besides paying attention to improvements, Grandshine conducts rigorous testing and validation. This ensures that the modified molds meet the desired performance standards. Testing and validation include trial runs and inspections to ensure that the molds produce high-quality parts.

Continuous Communication

Grandshine ensures to keep communication open and transparent with its customers throughout the manufacturing process. Communication is essential to understand your customer’s needs and to meet their expectations.

Documentation and Reporting

Grandshine offers its customers comprehensive documentation and reports regarding the details of the manufacturing process. These details include before-and-after data, changes made to the molds, and recommendations necessary for ongoing maintenance and care.

Fast Delivery Time

We consider our client’s success as our success. We have 20 years of experience, and meeting deadlines is our foremost preference. Due to our streamlined processes and efficient production capabilities, we prefer to give you the best results within 20 to 30 days. However, if our clients need our services on an urgent basis, we go over the edge to give you the best results within the given time frame.

Competitive Price

At Grandshine, we aim to provide valuable products and services to our clients. We offer our large-part injection molding services at competitive pricing that gives you strategic benefits in the market.

Our experts are familiar with optimizing production processes and reducing waste to give you a competitive price in the industry. We aim to provide cost-effective solutions to you without compromising on quality.

Grandshine- A Trusted Partner in Your Molding Journey

Grandshine’s wide range of large plastic mold products and comprehensive services, in combination with its commitment to quality and sustainability, make it the perfect partner for your plastic component requirements. Grandshine is here to bring your concepts to reality whether you work in the home appliances, automotive, or medical device industry.

Make Grandshine your trusted partner today so your projects meet the highest industry standards and bring you success.