Печать логотипа

Печать логотипаЧтобы решить проблемы, с которыми сталкиваются наши клиенты на других фабриках, мы прислушались к их отзывам. Многие клиенты сообщали о таких проблемах, как высокие минимальные объемы заказа (MOQ) для печати логотипа в других местах, а также о проблемах с неточностями цвета, нечеткой печатью, легким отслаиванием и неточностями в размере и размещении. В ответ на это Grandshine представила услугу печати логотипа на заказ, чтобы помочь нашим клиентам. Эта услуга обеспечивает четкую, точную и долговечную печать логотипа на различных продуктах. |

Печать индивидуального логотипаВ процессе печати логотипа мы предлагаем несколько вторичных методов обработки логотипа, включая шелкографию, лазерную печать, УФ-печать и 3D-печать. Наши профессиональные инженеры выберут процесс логотипа в зависимости от материала вашего продукта. Например, если ваш продукт представляет собой пластиковый чехол для телефона, мы можем использовать шелкографию, УФ-печать и 3D-печать. Если количество вашего продукта относительно небольшое, мы также можем предоставить лазерную печать логотипа для вторичной печати логотипа. Для изделий из сплава металла или дерева мы можем использовать лазерную печать логотипа для достижения печати логотипа вашей компании. Чтобы гарантировать точность цвета и размещения логотипа, мы предоставляем образцы визуализации логотипа и предпроизводственные образцы подтверждения перед печатью логотипа. Если вы хотите заказать печать логотипа, вы можете связаться с нами или отправить нам свою продукцию, мы можем предоставить вам услуги по печати бизнес-логотипа. |

|

|

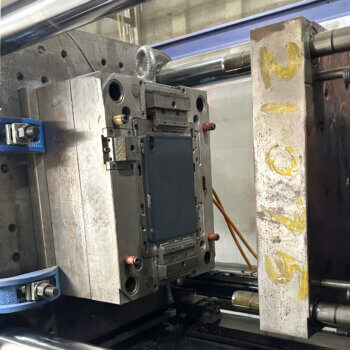

Вплавленный логотипIn-Mold Logo — это производственный процесс, который включает в себя впрыскивание цвета или материала с логотипом непосредственно в форму продукта, что позволяет формировать узор или логотип в процессе формования продукта. Мы всегда помещаем логотип вашего бренда в чертеж формы при проектировании 3D-чертежа формы. In-Mold Logo на продуктах более долговечен и менее подвержен износу, выцветанию или отслаиванию. In-Mold Logo обычно применяется в литьевых изделиях или изделиях из силиконовых форм, таких как пластиковые детали и силиконовые изделия. Если вы хотите включить логотип In-Mold в свои продукты, вам нужно будет разработать индивидуальный набор форм, которые станут вашей личной собственностью. Grandshine предлагает индивидуальные услуги по изготовлению форм для логотипа In-Mold. Не стесняйтесь спрашивать о наших услугах по логотипу In-Mold и отправляйтесь в свое уникальное путешествие по брендингу. |

Тестирование печати логотипаНезависимо от используемой техники печати логотипа мы проводим испытания каждого логотипа на спиртоустойчивость и истираемость, чтобы гарантировать правильность, долговечность и четкую видимость. |

|