This website uses cookies to ensure you get the best experience Privacy policy

About Us

— Contact Grandshine And Boom Your Business —

Play Video about shiping zhutu

Shenzhen Grandshine Technology Co., Ltd is a leading professional in new product development and plastic mold manufacturer with over 20 years experience. With bases in Shenzhen China, Los Angeles USA as well as Singapore, Grandshine specializes in new product design, custom plastic injection mold, silicone mould, plastic parts, die casting, stamping mould, product assembly and large-scale production, offering comprehensive one-stop supply chain.

Over the years, our products range has encompassed phone accessories, tablet accessories, gaming accessories, industry equipment, pet products and various consumer electronic items.

We provide complete manufacturing solution, include products design, prototype, molding, mass production and final assembly to satisfy your supply chain requirements. With our new product development team, you can get service of industrial design, mechanical design, mold design, electronic design, FPC PCBA design etc.

Our facilities include plastic mold manufacture plant, plastic injection, silicone manufacture, leather sewing, FPC PCBA manufacturing, second processing and assembly line. These factories can help you make your product design ideas become to finished products with one-stop services.

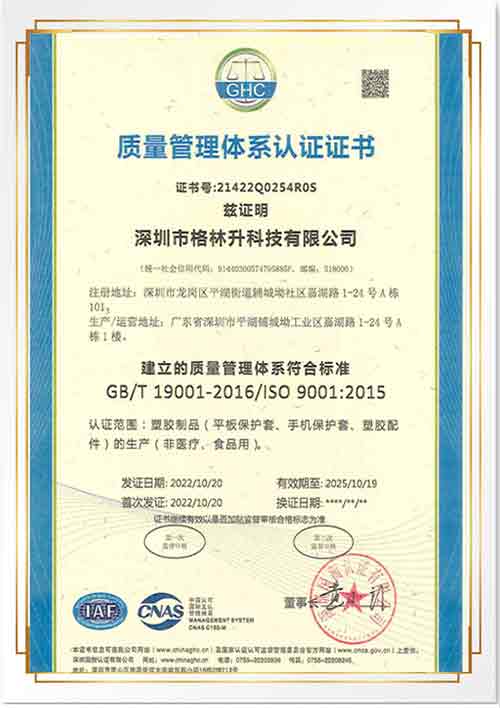

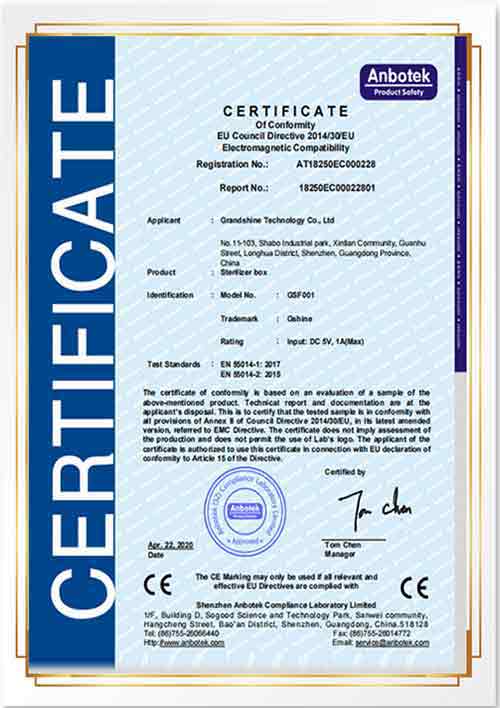

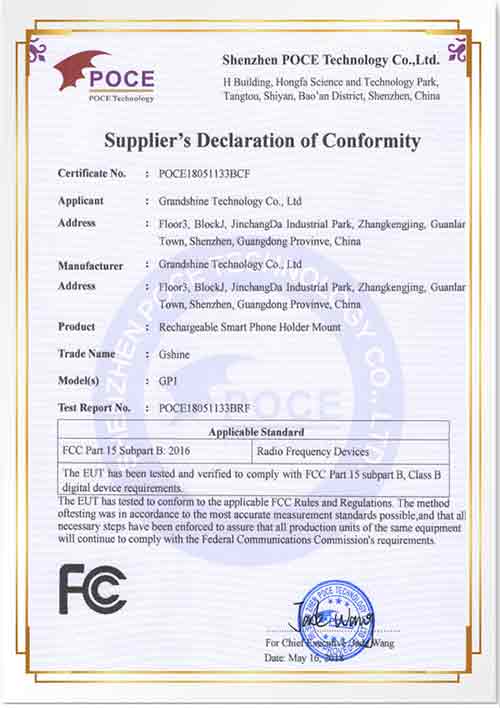

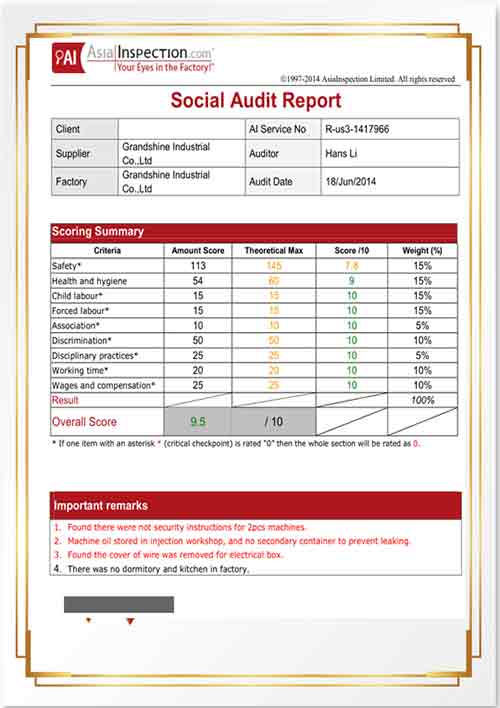

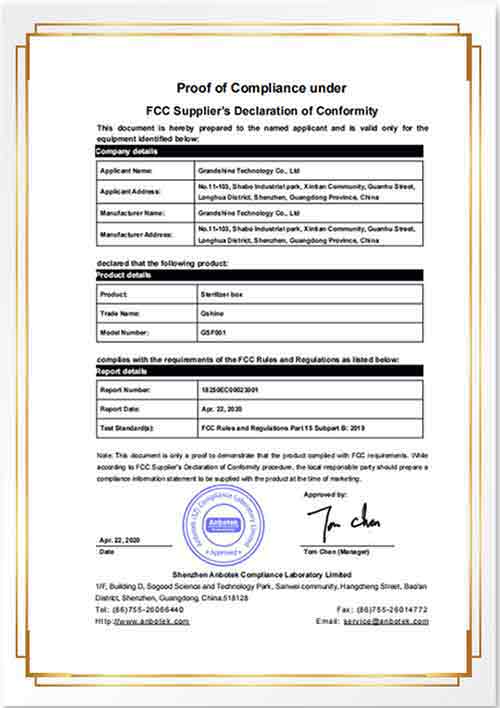

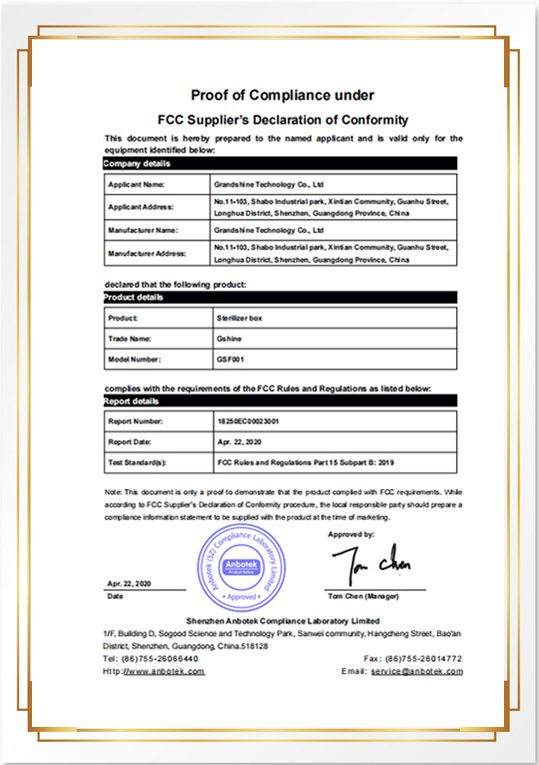

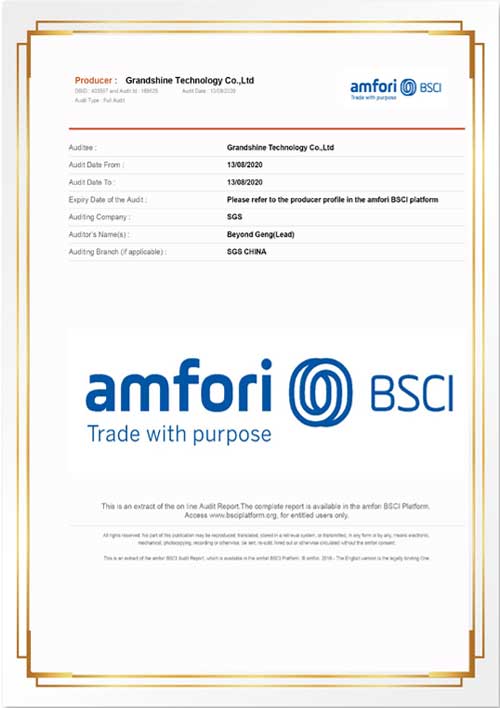

Presently, Grandshine factory has passed ISO9001:2015 quality management system certification, ISO14001:2015 environment management system certification and BSCI B level social factory audit by SGS. There certification and audit reports can enable our customers’ products access to big market channels such as Walmart, Tesco, Aldi, Target, Kmart etc.

To facilitate your importing process, we established office and assembly line in China, USA and Singapore. Welcome to visit our factories and local office when you come. Thank you.

— Meet Our Managing Team —

Ken - CEO

Shareholder Of 6 Companies With 17 Year Managing Experience .

Rosalin - VP & CFO

15 Years Big Customers Cooperation Experience.

Kenneth - CTO & COO

20 Years Product Design & Manufacture Engineering Experience.

Andy Yin - Senior Quality Inspector

5 Years Quality System Management Experience in Foxconn.

Kaiwin - Sales Director

12 Years Market Experience & Product Design Proposal Expert.

Lucas - Africa Market Manager

6 Years Asia & Africa Market Development Experience.

Andy Yin - Senior Quality Inspector

5 Years Quality System Management Experience in Foxconn.

— Products Test Inspection Equipment & Lab —

Friction Test Machine

For our products, the firmness of the surface is very important. After secondary spraying or logo pattern printing for each product, we will carry out 5000 to 20000 wear-resistant tests to ensure that our Grandshine products can meet various use environments and ensure that the surface pattern of our products is firm and reliable. Choose Grandshine, we will provide you with quality products.

Drop Test Machine

All Grandshine products use shock-absorbing materials and design, and the rugged case surpasses military standard drop tests to achieve a whole new level of protection. Before each product leaves the factory, we will carry out the drop test on the four corners and six sides of the product, the test height is 3FT-9ft, we ensure that each product is with strong protection. So whether it's a crush on your commute or an accident falling off your desk, your iPad device is safe from falling or other mishaps.

Salt spray test equipment

Whether it's tablet accessories or other comsumer electronic products, these products will be used in a variety of natural environments, so we need to ensure that all products supplies have good corrosion resistance. then you can provide a durable and quality products for your customers. The salt spray test chamber tests the corrosion resistance of all Grandshine products after surface treatment, including coating, plating, organic and inorganic skin film, anodic treatment, rust oil and other anti-corrosion treatments,all Grandshine supplies products have to be passed salt spray test before shipment to ensure the quality of the product.

Quadratic Measuring Instrument

The quadratic measuring instrument is used to measure the size of products and molds. The measuring elements include position degree, concentricity degree, straightness degree, contour degree, roundness and the size related to the benchmark. The instrument is suitable for the purpose of two-coordinate measurement in all application fields, machinery, electronics, instruments, hardware, plastic, mold, accessories, rubber, PCB board, etc. Measurement of various metal processing parts, stamping parts, plastic parts of diameter, length, Angle, hole position, etc.; Measuring the shape of various molding parts such as template, template turning tool, template milling tool, stamping die and CAM; Measuring the geometric parameters of various tools, molds and measuring tools; Measuring thread plug gauge, screw and worm thread diameter, large diameter, small path, pitch, tooth type half Angle; Measurement of gear hob lead, tooth shape and tooth shape Angle; Measure the length, width, distance and dimension and position of solder holes on printed circuit boards; Measurement of 2-D shape and position tolerance of various parts.