Tips Of Designing Plastic Components For Automotive Industry

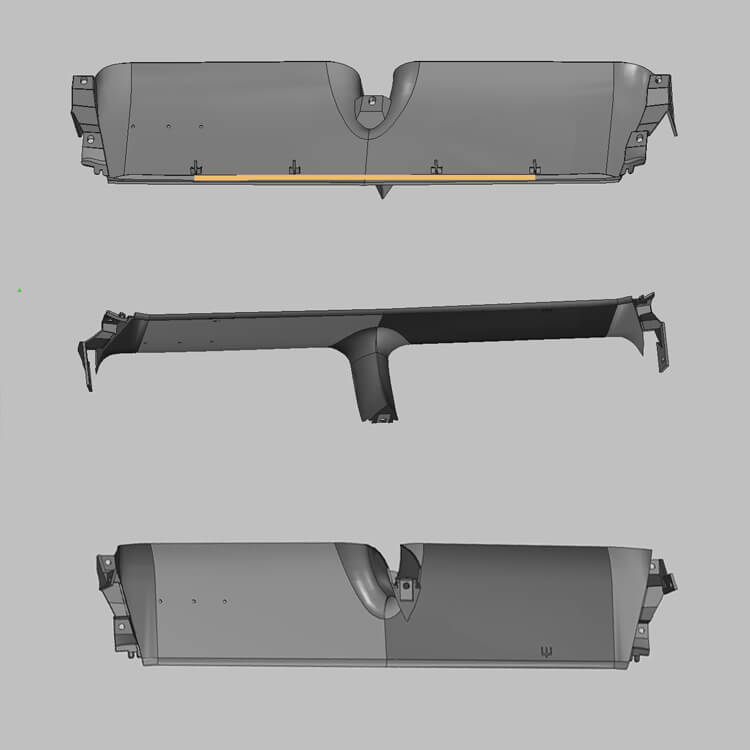

As a professional product manufacturing factory, Grandshine recently received a request from a client in the United States to design and produce a plastic mould for an automotive middle wing. After careful consideration and collaboration with our engineering team, we were able to produce a high-precision mould with a length of 1.2m.

Once the mould was completed, we proceeded with the testing phase to ensure its quality and precision. Our experienced technicians worked tirelessly to guarantee that every aspect of the product met our strict quality control standards. We then sent T1 samples to the client for confirmation before proceeding with mass production.

Our professional services don’t stop here. We understand that every client has unique needs and requirements, which is why we work closely with them throughout the entire production process. From material selection to product design, testing, and final delivery, we offer customized solutions to meet our clients’ individual needs.

When it comes to designing plastic components for the automotive industry, there are several factors we consider. These include material selection, precision size, durability, safety, and aesthetic appeal. At Grandshine, we prioritize the quality and safety of our products, ensuring that they meet strict industry standards and regulations.

We also take pride in our high level of customer service, providing fast and efficient communication, as well as timely updates on project progress. We believe that transparency, reliability, and professionalism are essential elements in building long-term relationships with our clients.

In terms of designing automotive plastic components, there are several key considerations to keep in mind. Firstly, material selection is crucial. It’s important to choose materials that meet industry standards and regulations, such as ABS, PC, and PP, to ensure quality and safety. At Grandshine, we conduct rigorous functionality testing, including drop tests, impact tests, and salt spray tests, to ensure that the selected material provides the necessary reliability.

Secondly, precision size is also essential when designing automotive components. High-precision production processes and advanced technology are necessary to ensure that each component meets strict quality control standards. At Grandshine, our experienced engineers can achieve precision as high as 0.001, and we use second and third-dimensional instruments to test products to ensure they meet the required size standards.

Thirdly, durability is also a critical factor to consider when designing automotive components. They need to be able to withstand harsh environments, such as extreme temperatures and corrosive substances. At Grandshine, we conduct high and low-temperature tests, as well as salt spray tests, to ensure that our products remain durable and reliable in any environment.

Fourthly, safety is of utmost importance when it comes to designing automotive components. As driving is a high-risk activity, plastic components should be designed to absorb energy effectively in the event of an accident, reducing the risk of injury to both the driver and passengers.

Finally, aesthetic appeal is also vital. Plastic components should not only be functional but also look good. At Grandshine, we offer services such as polishing or graining, and secondary process painting or plating to enhance the product’s appearance, giving it higher sales value.

In conclusion, if you need professional and customized product manufacturing services, look no further than Grandshine. Our years of experience, commitment to quality, and personalized services make us the perfect choice for any project, be it large or small.

Tips:

Always work with a reputable and experienced manufacturer when designing plastic components for the automotive industry.

Conduct extensive research on materials and their properties to ensure that they meet industry standards and regulations.

Prioritize safety, durability, and aesthetic appeal when designing products.

Work closely with your manufacturer throughout the entire production process to ensure that your unique needs and requirements are met.

Choose a manufacturer that values transparency, reliability, and professionalism in their services.

Related Posts

Quality Assurance & Quality Control | Definition-Difference-Methods-Process

what is the injection molding-part1

Some tips help you understand electric injection molding machines