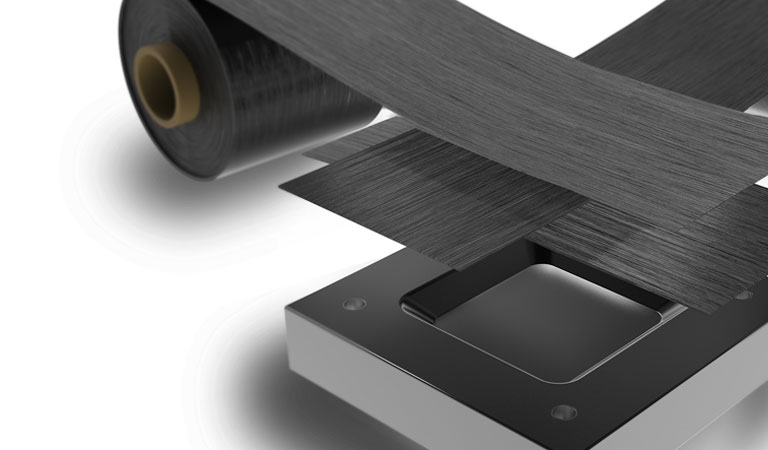

Whats glass fiber plastic:

Glass fiber reinforced plastic is based on the original pure plastic, adding glass fiber and other additives, so as to improve the scope of use of the material. Generally speaking, most of the glass fiber reinforced materials are used in the structural parts of the product, which is a structural engineering material; For example: PP ABS PA66 PA6 PC POM PPO PET PBT PPS

Advantages:

- After glass fiber reinforcement, glass fiber is a high temperature resistant material, therefore, the heat resistance temperature of reinforced plastics is much higher than before without glass fiber, especially nylon plastics.

- After glass fiber reinforcement, the mutual movement between the polymer chains of plastics is limited, so the shrinkage rate of reinforced plastics is reduced a lot, and the rigidity is greatly improved.

- After glass fiber reinforcement, the reinforced plastic will not stress crack, and at the same time, the impact resistance of the plastic is improved a lot

- After glass fiber reinforcement, glass fiber is a high-strength material, which also greatly improves the strength of plastics, such as: tensile strength, compressive strength, bending strength, and so on

- After glass fiber reinforcement, due to the addition of glass fiber and other additives, the combustion performance of reinforced plastics is reduced a lot, and most of the materials can not be ignited, which is a flame retardant material

Weaknesses:

- After glass fiber reinforcement, the transparent material will become opaque due to the addition of glass fiber.

- After glass fiber reinforcement, the toughness of all plastics decreases, while the brittleness increases.

- After glass fiber reinforcement, the molten viscosity of all materials increases, the fluidity becomes worse, and the injection pressure increases much more than that without glass fiber.

- After glass fiber reinforcement, the injection temperature of all reinforced plastics should be increased by 10℃-30℃ than before without glass fiber

- After the glass fiber reinforcement, the hygroscopic performance of the reinforced plastic is greatly strengthened, and the original pure plastic that does not absorb water will also become absorbent, therefore, the injection molding should be dried.

- After the glass fiber reinforcement, during the injection molding process, the glass fiber can enter the surface of the plastic product, making the surface of the product very rough. In order to obtain a high surface quality.

- After the glass fiber reinforcement, the glass fiber is a material with high hardness, and the additives are highly corrosive gases after volatilization at high temperature. The wear and corrosion of the screw and injection mold of the injection molding machine is very great

Application:

Glass fiber reinforced plastics are widely used in many fields for their excellent strength, light weight and durability. In automotive manufacturing, it is used to produce doors, engine covers, roofs, instrument panels, door panels, seat frames, beams, brackets, frames, etc. In the construction industry, its weather resistance and corrosion resistance are used to manufacture window frames, door frames and other building materials. In electronic and electrical equipment, mobile phone shell, TV shell, external parts are also widely used this material. Golf clubs, bicycle frames, skateboards and scooters also give full play to the advantages of glass fiber reinforced plastics in applications, further boosting their market position.

Related Posts

Quality Assurance & Quality Control | Definition-Difference-Methods-Process

what is the injection molding-part1

Some tips help you understand electric injection molding machines