Product

Product Catalog

-

Charger65W Dual Port Fast Charger

Travel Charger

Model:

GAN652-EU-P

Input:

100-240V~50/60Hz 1.5A

Type-C Output:

5.0V-3.0A 15W Max

9.0V-3.0A 27.0W Max

12.0V-3.0A 36.0W Max

15.0V-3.0A 45W Max

20.0V-3.25A 65.0W MaxPPS:

5.9-11.0V-4.0A 44.0W Max

USB-A Output:

5.0V-2.4A 12.0W Max

Type-C&USB-A Output

Type-C Output:

5.0V-3.0A 15.0W Max

9.0V-3.0A 27.0W Max

12.0V-3.0A 36.0W Max

15.0V-3.0A 45W Max

20.0V-2.25A 45W MaxPPS:

5.9-11.0V-4.0A 44.0W Max

USB-A Output:

5.0V-2.4A 12.0W Max

-

Charger50000mAh Power Bank

50000mAh

Model:

F50

Batery Capaclty:

50000mAh/3.7V

Power:

185Wh

OUT(Type-C):PPS:

3.3V~11V,3V

IN/OUT(TYPE-C1):

5V-3A/9V-3A/12V-3A/15V-3A/20V-5A(PD100W)

IN/OUT(TYPE-C2):

5V-3A/9V-3A/12V-3A15V-3A20V-3.25A(PD65W)

OUT(USB-A):

5V-3A/9V-2A/12V-1.5AQC18W)

Standard:

GB/31241-2022

-

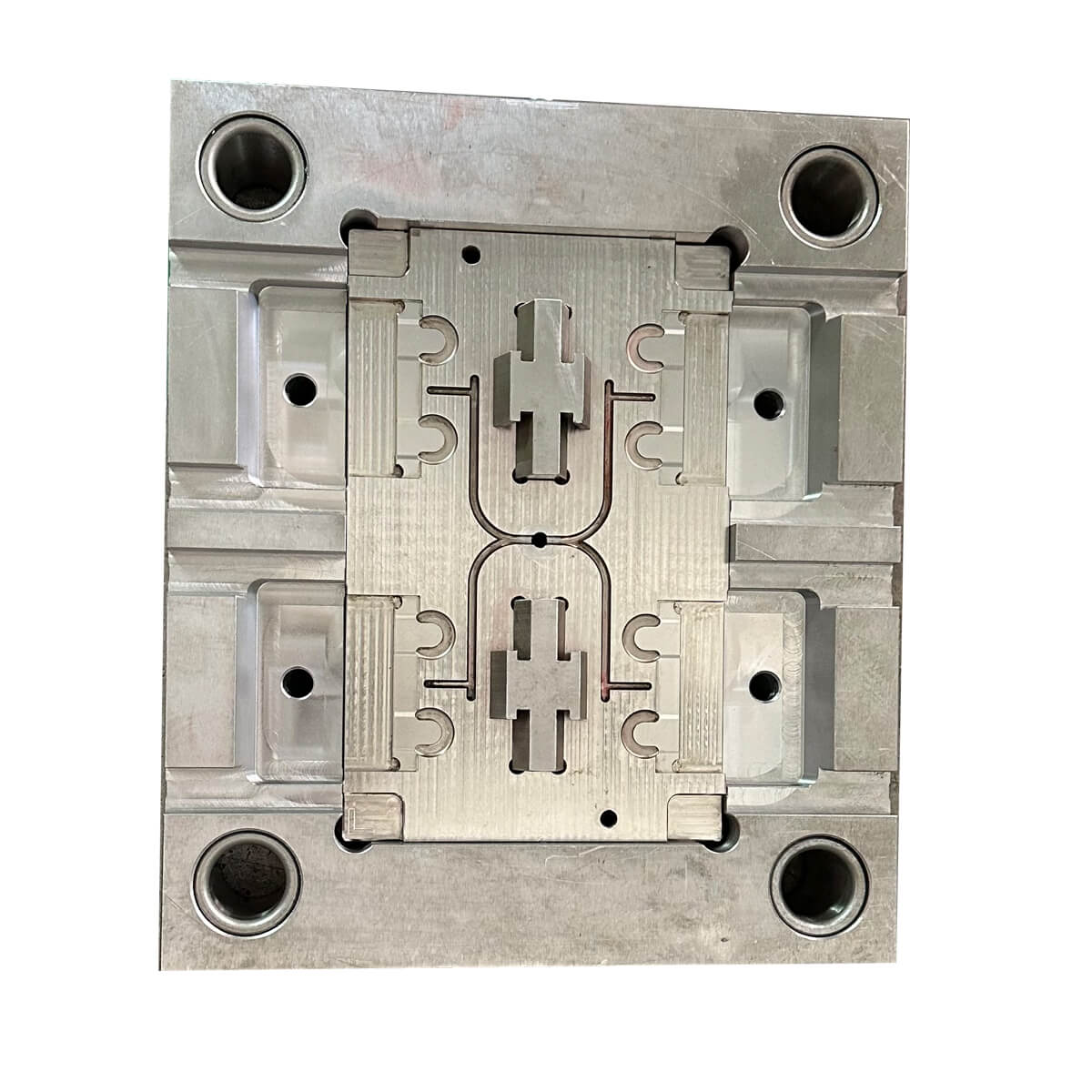

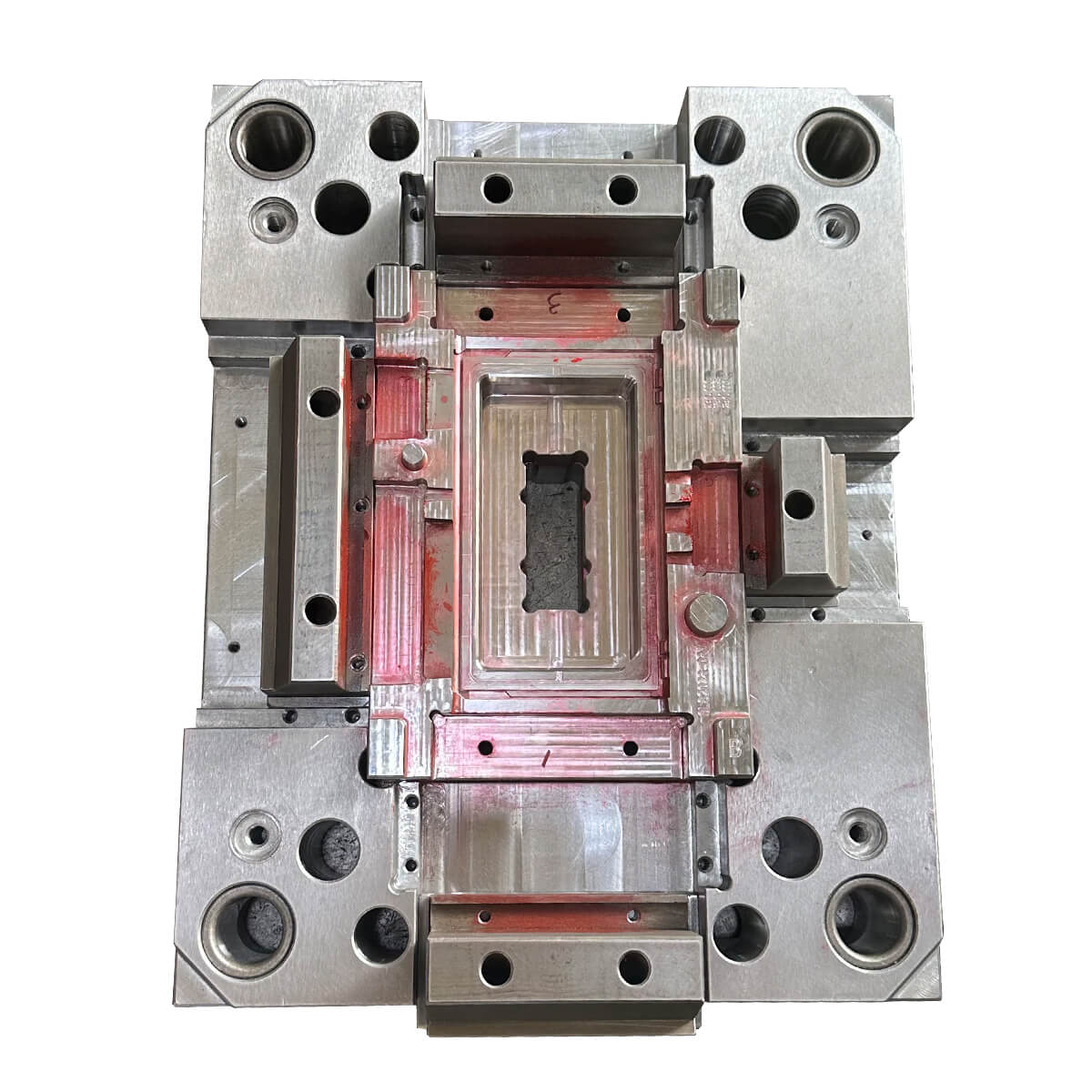

Injection Mold ToolingPrecision Injection Molding / Made In Malaysia

Grandshine is a leading manufacturer of precision injection molding with a strong presence in China and Malaysia. Grandshine provides top-tier injection molding services for various industries due to its commitment to precision and excellence.

Our global footprint ensures that we can help you save on import tariffs by providing manufacturing in Malaysia. In contrast, our extensive industry coverage ensures we can meet your specific requirements efficiently and cost-effectively.

-

Injection Mold ToolingPlastic Injection Molds – ISO9001 Factory

Plastic injection molds play a crucial role in the manufacturing industry, resulting in a wide range of everyday products. However, customers face numerous challenges when it comes to these molds. That’s why Grandshine, a leading mold manufacturing industry, addresses these problems in the right way.

In the world of injection molds, the challenges customers face can be significant, affecting product quality, sustainability, and efficiency. However, Grandshine is a trusted solution provider for these challenges due to its design expertise, high-quality materials, and precision manufacturing. If you choose Grandshine, you choose sustainability, excellence, and ethical manufacturing.

-

Injection Mold ToolingProfessional New Products OEM/ODM Custom Molders

Nowadays, staying ahead in the competitive business market needs constant innovation and the ability to bring new, exciting products to your customers. One way to achieve this is through Grandshine’s OEM/ ODM custom molder service. In the world of custom molders, Grandshine is your trusted partner for transforming your product ideas into reality.

Grandshine’s OEM/ODM custom molding services are your gateway to successful new product development. You can confidently innovate and bring exceptional products to the market by getting help from Grandshine’s expertise. Contact Grandshine today and take the first step toward turning your product ideas into reality.

-

Injection Mold ToolingTop 3 Plastic Molding Manufacturers in Shenzhen

Plastic molding has become a crucial process in the rapidly evolving world of manufacturing and product development. It provides a versatile and cost-effective way of producing a wide range of products. Grandshine, a leading company in the field of injection molding, has become a trusted name in the industry as it offers numerous advantages that make it different from its competitors.

This listing highlights Grandshine’s molding capabilities, how you will benefit from customizing your molding needs with them, and shows some successful projects that ensure their commitment to quality and innovation.

-

Injection Mold ToolingPolypropylene Molding / Reasonable Price Molding Manufacture

Polypropylene manufacturing is a cost-effective and versatile manufacturing process with a wide range of applications across a variety of industries. Polypropylene (PP) is a thermoplastic addition polymer commonly used in injection molding applications. Due to its semi-crystalline nature, it has high flexural strength.

Let’s take a deeper look at the features of polypropylene molding and how you can benefit from strategic partnerships with companies like.

-

Injection Mold ToolingPlastic Injection Molding Service- 20 Years Experience

Plastic injection molding service refers to a manufacturing process employed in the mass fabrication of various plastic parts. It is primarily preferable for the production of large volumes of plastic components due to its precision, versatility, and efficiency.

Molding services include an injection of molten plastic into the mold, where it cools and takes on its final shape. The customization of the mold is done during tooling, resulting in the shape of the part. Consequently, you can create numerous identical and uniform-dimension parts in addition to complex designed parts and those that only bear low dimensional tolerance.

Plastic injection molding services are utilized in various industries, from automotive and aerospace to electronics, consumer goods, and more. The key aspects of these services include mold creation, material selection, melting and injection, cooling, ejection, quality control, and repetition.

-

Injection Mold ToolingInjection Molding Products / 10-25 Days Fast Delivery Mold Tooling

In recent years, there are significant advancements being witnessed in the world of manufacturing. However, mold design and manufacturing stand at the forefront of this progress. Precision and mold quality are crucial elements in various industries, from consumer goods to automotive and aerospace. Grandshine stands out as a leading manufacturing industry when it comes to injection molding products, with Japan’s modern production equipment, automation, and robotics.

In this listing, we will explore the capabilities of Grandshine, with 20 years of experience, equipped with the latest technology and expertise, and its high-quality mold design and manufacturing services. So, let’s start.

-

Mass Production & AssemblyInjection Molding Manufacturer / Low-Volume Plastic Manufacturing

Finding a trusted partner for low-volume injection molding is essential in the fast-moving world of product development and startup ventures. Grandshine, a leading injection molding manufacturer, steps in to provide tailored solutions to fulfill the unique needs of innovative projects and new businesses.

Whether you are looking for low-volume products for market testing or struggling with a limited budget, Grandshine is here to help you grow. 500-1000pcs moq is supported for your new products development.

-

Logo PrintLarge Plastic Mold Maker / ISO14001:2015 Certificated Factory

As one ISO14001:2015 certificated and ISO9001:2015 certificated large plastic mould maker, Grandshine has always been concerned about environmental protection and sustainability, and ISO 14001 is an environmental management system standard that helps to manage and reduce environmental impact.

-

Injection Mold ToolingUSA Standard Injection Molding / USA Local Office

In today’s fast-paced manufacturing landscape, companies in the United States are constantly looking for innovative solutions to fulfill their custom injection molding needs. Grandshine USA, having its local office and modern assembly line, has originated as a leading player in the industry, providing numerous benefits to American customers.

Grandshine USA has placed itself as a frontline partner for injection molding services. The company offers a wide range of unique benefits, including exceptional quality, competitive pricing, local accessibility, and a full set of services. Although businesses continue to adapt to the evolving demands of the manufacturing industry, Grandshine USA remains a trusted partner, looking forward to exceeding the expectations of American customers.

Our end to end product development service range has emcompassed phone accessories, tablet accessories, industry device accessories, gaming accessories and various comsumer electronic items.