First, accept the mission statement

Manufacture of plastic parts of the task book is usually proposed by the part designer, including: after reviewing and signing the formal parts drawings, indicating the plastic grade used, transparency, etc.. Plastic parts instructions or technical requirements. Production quantities. Samples of plastic parts.

Usually, the task of mold design by the plastic parts processor according to the molding of plastic parts task proposed. Mold designers based on molding plastic parts task book and mold design task book to design molds.

Second, collect, analyze and digest the original data

Analyze plastic parts drawings, understand the purpose of the parts, analyze the plastic parts of the process, dimensional accuracy and other technical requirements. For example, plastic parts in the appearance, color transparency, the use of performance requirements, as well as plastic parts of the geometric structure, slope, inserts and other circumstances are reasonable.

Analyze the process data to determine the appropriateness of the molding method, equipment type, material specifications, mold structure type and other requirements.

Determine the molding method – whether to use the direct pressure method, casting method or injection method. Select molding equipment, understand the performance, specifications, characteristics of various molding equipment.

Third, the factors affecting the mold structure and individual systems of the mold:

Determine the type and main structure of the mold to meet the requirements of process technology and production economy of plastic parts. Consider the geometric shape of plastic parts, surface finish and dimensional accuracy and other process technology requirements, as well as cost, production efficiency, the service life of the mold and other production economic requirements.

Consider the factors affecting the mold structure and individual systems of the mold, such as cavity arrangement, parting surface determination, pouring system, exhaust system, ejector mode, cooling, heating mode, etc..

According to the mold material, strength calculation or empirical data, determine the thickness of the mold parts, external dimensions, external structure and the location of all connecting, positioning and guiding parts.

Determine the structural form of the main molding parts and structural components, consider the strength of each part of the mold, and calculate the working size of the molding parts.

After the above problems are solved, the structural form of the mold is also solved. Next should start to draw the mold structure sketch, for the formal drawing ready.

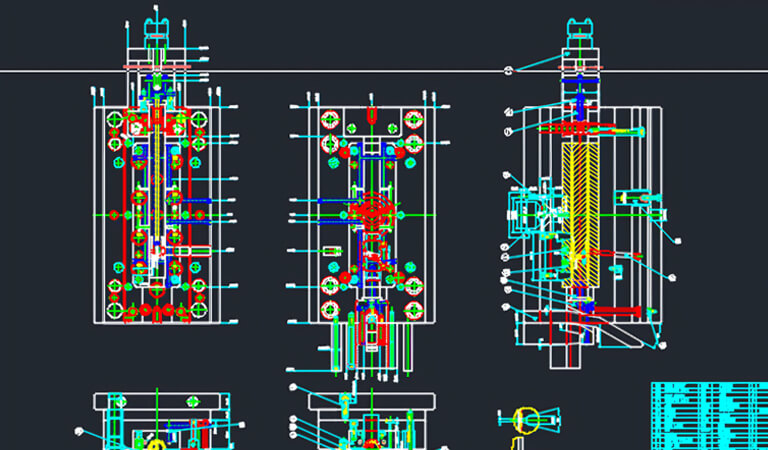

Fourth, drawing mold map

According to the international drawing standards for drawing molds, while combining the factory standards and factory customary drawing. Before drawing the mold assembly diagram, should first draw the process diagram, and meet the requirements of the parts map and process information. For the dimensions guaranteed by the next process, should be labeled “process dimensions” on the diagram. In the mold assembly drawing, drawing assembly structure, try to use 1:1 ratio, starting from the cavity drawing, while drawing the main view and other views.

Fifth, the contents of the mold assembly drawing include:

Mold molding part of the structure.

The structure of the casting system, exhaust system form.

The parting surface and the way to take parts of the mold.

Shape structure, the location of all connectors, positioning and guiding parts.

Cavity height dimensions (if required) and overall mold dimensions.

Auxiliary tools (pick-up and unloading tools, alignment tools, etc.).

Compile all the part numbers in order and fill in the detailed list.

Labeling technical requirements and instructions for use.

Sixth, the technical requirements of the mold assembly diagram should include:

Performance requirements for certain systems of the mold, such as ejector system, slide core structure of the assembly requirements.

Requirements for the mold assembly process, such as mold assembly after the parting surface of the fit gap of not more than 0.05mm, the mold on the following parallelism requirements, and pointed out the size of the assembly decision and the requirements of the size. Including mold use, assembly and disassembly methods. Antioxidant treatment, mold numbering, lettering, marking, oil sealing, storage and other requirements.

Requirements for mold testing and inspection.

Seven, draw all the parts:

The mold assembly diagram is divided into parts drawings, in the order of first inside and then outside, first complex and then simple, first molding parts and then structural parts. Graphics should be drawn to scale, view selection is reasonable, the projection is correct, clear and legible. Marking dimensions should be unified, concentrated, orderly and complete, in accordance with the main parts size, mold slant, with the order of the dimensions marked. Surface roughness and other content should also be filled out correctly.

Eight, proofreading, auditing, tracing, sending sun:

Self-proofreading includes the relationship between the mold and plastic parts drawings, plastic parts, molding equipment, mold structure check. Professional proofreading focuses on structural principles, process performance and operational safety aspects of the check. When tracing the drawing, it should be depicted according to the requirements of national standards, fill in all dimensions and technical requirements, and proofread and sign by itself. After the bottom drawing is proofread and signed by the designer, it is submitted to the relevant technicians for review to confirm the manufacturing process. Prepare the manufacturing process card, prepared by the technicians, and ready for processing and manufacturing.

Nine, test mold and mold repair:

Conduct trial mold test, observe the quality of the parts, and repair the mold when problems are found. Before repairing the mold need to analyze and study the bad phenomenon of plastic parts, according to the situation to change the molding conditions, only when the change can not solve the problem, consider repairing the mold. Repair molds need to be careful, because once changed the mold conditions, it will be difficult to restore the original state.

Ten, organize the information for archiving:

After the completion of the mold test, if not used for the time being, it should be thoroughly cleaned, rust-proof and stored in the storage place. For the mold design, processing, inspection and other processes generated in the technical information, such as the task book, parts map, mold map, etc., should be in accordance with the provisions of the collation, binding, numbering and archiving, in order to prepare for future repair of the mold or the design of a new mold for reference use.

These are the ten main steps in plastic mold design.

Related Posts

Quality Assurance & Quality Control | Definition-Difference-Methods-Process

what is the injection molding-part1

Some tips help you understand electric injection molding machines