Injection Molding

There is no more suitable means of processing TPU than screw-type injection molding machines. Single-threaded, three-stage screws of usual lengths can produce a very well plasticized, homogeneous melt. If a high plasticizing capacity (production volume) is required, longer screws can be used. Short compression zone screws are not suitable due to high shear forces. the high energy required for TPU plasticizing requires high torque to drive the screw. Insufficient torque results in fluctuating screw speeds and uneven plasticization. Within limits, higher barrel temperatures produce good results, although there is a risk of overheating the material.

The access to the nozzle and screw head should be designed so that there is no dead space and the material can be injected without thermal damage. Accurate temperature control of the barrel and nozzle heating system is essential. Care should be taken to ensure that the nozzle is heated uniformly over its entire length. Beware of localized overheating and possible cooling of the melt in the pathway. The molten TPU is neither corrosive nor abrasive. For this reason, the screw does not require any special alloy steel or reinforced plating.

Temperature setting of the screw barrel and mold

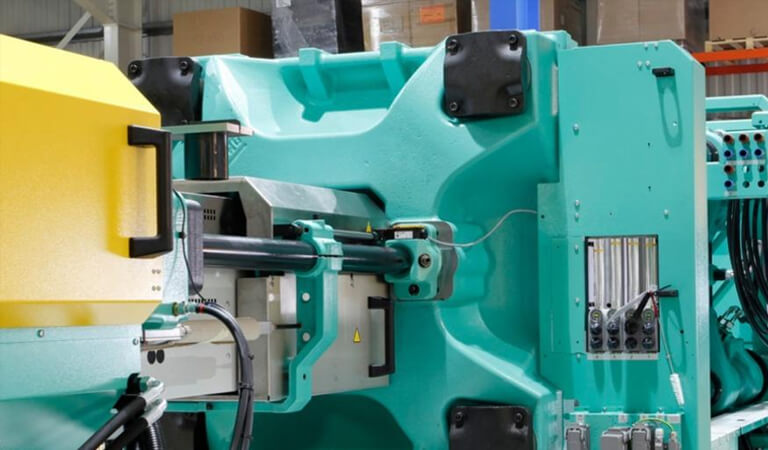

2.1 Injection unit

TPUs should be processed at melt temperatures between 190°C and 220°C. For some hard grades, the melt temperature should be set at a temperature of between 0.5°C and 0.5°C. For some hard grades the melt temperature may be increased to 240°C. The melt temperature range for specific grades of TPU can be found in the relevant product information sheet.

2.2 Mold

The main influence of the mold temperature is on the surface quality and release behavior. It also affects the shrinkage of the final structure and internal stresses (when cold). Normal mold temperatures should be applied between 20°C and 40°C. However, with some modified TPU grades and the use of glass-filled reinforced TPU, the mold temperature should be increased to 60°C to ensure optimum surface quality. For cooling thick-walled articles, a reduction of approximately 5°C can reduce cycle time.

Plasticizing

For the plasticizing speed a circumferential rate of not more than 0.3 m/s should be selected. the metering stroke should be between 1 D and 4 D. The metering stroke should be between 1 D and 4 D. The metering stroke should be between 1 D and 4 D. Experience has shown that utilizing 30% to 75% of the screw barrel capacity is optimal. If the screw barrel capacity corresponds to a very low injection volume, the melt stays too long in the plasticizing unit. This can lead to thermal damage of the melt.

Injection Pressure, Holding Pressure, Back Pressure, Injection Speed

For ideal processing, the key point is uninterrupted control of pressure and injection speed. It should be possible to control the injection and holding pressure in the range of 100 to 1200 bar. Back pressure is necessary for homogenization and is usually set between 1 and 2.5% of the injection pressure. The injection speed is mainly based on the wall thickness. Typically molds for thick walled items need to be filled slowly, while thin walled items need to be filled quickly.

Cycle Time

The cycle time is determined by the shape of the article, the wall thickness, the cooling of the mold and the material itself.

Demolding

Reproduction molds for TPU need to be described in detail. Soft grades of TPU are peculiar in that they can produce items with too many unusual walls. This must be taken into account when designing the mold. Mold release can be accomplished with the use of a mold release agent. Silane-based release agents such as Baysilon M work well. Non-silane based release agents are also possible but must be used frequently.

Scrap recycling

Crushed material from scrap, sprues, rejects, etc. can be recycled into pellets if cleaned and dried. For injection molding, adding less than 30% of pulverized material to pure material will not affect the performance of the product. If you process your own pulverized material, the molded item must be tested to determine if it meets the performance requirements. For extrusion it is inappropriate to mix pulverized material with pure material (because of the different viscosities). It is not absolutely unacceptable to use pure homogeneous crushed material for extrusion, but it is perfectly acceptable for injection molding.

Mold Design / Contour Structure

TPU molds should be made of the same type of steel used for thermoforming. Simple and small products tend to be made of aluminum alloy. For prototype molds, cast resin or die-cast metal inserts can be used normally.

Additives

In order to improve processing characteristics and special behavior, we recommend the addition of commonly used functional masterbatches such as:

Anti-tack agents

Mold release agents

UV stabilizers

All must be pre-dried before addition.

These are key points in TPU injection molding and each step needs to be carefully considered and controlled to ensure that the quality and performance of the final product meets expectations.

Related Posts

Quality Assurance & Quality Control | Definition-Difference-Methods-Process

what is the injection molding-part1

Some tips help you understand electric injection molding machines