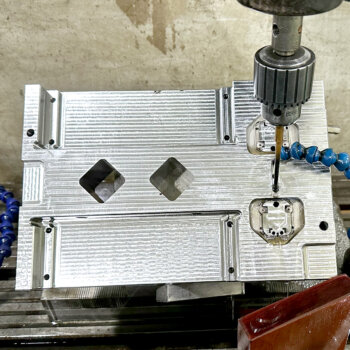

Here is a range of custom plastic parts that Grandshine offers:

Grandshine’s Custom Plastic Parts Range

Grandshine is here to provide a wide range of custom-molded plastic parts to meet diverse industrial requirements. Our extensive molding capabilities include:

ABS Injection Molding

Acrylonitrile Butadiene Styrene (ABS) is popular for its impact resistance and versatility. Therefore, it is a preferred choice for numerous consumer goods.

Polycarbonate Injection Molding

Polycarbonate is known due to its transparency and exceptional strength. That’s why it is ideal for applications that need optical clarity and durability.

PLA Injection Molding

Polylactic acid (PLA) is an environmentally friendly bio-plastic, making it a perfect choice for sustainable and biodegradable solutions.

TPU Plastic Molding

Thermoplastic Polyurethane (TPU) possesses excellent flexibility and abrasion resistance. That said, it’s a suitable option for items like gaskets, seals, and soft-touch components.

HDPE Molding

High-density polyethylene (HDPE) has incredible durability and chemical resistance. So, it’s the best choice for piping, containers, and more.

POM Injection Molding

Polyoxymethylene (POM), also called acetal, possesses low friction and high stiffness. Therefore, it is preferred for bearings, gears, and mechanical components.

Acrylic Injection Molding

Due to its remarkable optical clarity, weatherability, and UV resistance, acrylic is used in industries like signage and displays.

Silicon Molding

Silicon is well-known for its flexibility, biocompatibility, and heat resistance, making it preferable for kitchen and medical applications.

PVC Molding

Polyvinyl Chloride (PVC) is known for its chemical resistance and electrical insulation. That said, it is employed in various applications like construction and electronics.

Material Selection Expertise

Choosing the suitable material for your custom molded plastic parts is crucial to ensure performance and functionality. Our team of experts at Grandshine stands out in material selection as we consider the following factors when it comes to selecting the appropriate material:

High Strength

In the case where the demand of your applications is rigid parts, materials like ABS, PVC, and polycarbonate provide exceptional strength as well as impact resistance.

Wear Resistance

For components that need to withstand wear and friction frequently, materials like POM, HDPE, and ABS are recommended; they are known for their low-friction properties and durability.

High-Temperature Resistance

Materials such as POM and silicone are suitable for environments where elevated temperature is a significant concern. One distinguishing feature of these materials is that they withstand heat without losing integrity.

Our expert team at Grandshine understands better that each project has unique requirements. Therefore, we work closely with you to understand your needs and suggest you the best materials, so your custom plastic parts meet the highest standards.

Contact Grandshine Today for Your Plastic Parts Manufacturing Needs

Choosing the right and reliable partner for the manufacturing of the plastic parts is crucial. That said, we at Grandshine are dedicated to ensuring excellence at each step of the manufacturing process. Whether your demand is prototype, small runs, or large-scale production, our facilities and skilled team look forward to providing results that exceed your expectations.

Here is what you will get if you collaborate with Grandshine:

- Efficient production to meet your deadlines

- Ensuring quality control so your parts can meet the industry standards.

- Precision and accuracy in every manufactured component

- Competitive pricing so your project remains within budget

- Committed to a sustainable environment by providing eco-friendly materials such as PLA

Once you collaborate with Grandshine, you are not just a client; you are a collaborator in the creative process. From day one, we work closely with you from the initial design phase to the final delivery. Our team is here to guide you regarding material selection, design consideration, and prototyping so the end result aligns perfectly with your vision.

In addition, we understand the importance of clear communication. Therefore, we are always ready to address your queries 24/7 throughout your project process. You can easily collaborate with us.

Email us today at kaiwin@grashine.com so we can bring life to your reality. We offer a seamless process from design and prototyping to production and delivery. We are proud to provide innovative solutions that help your products stand out in the market.