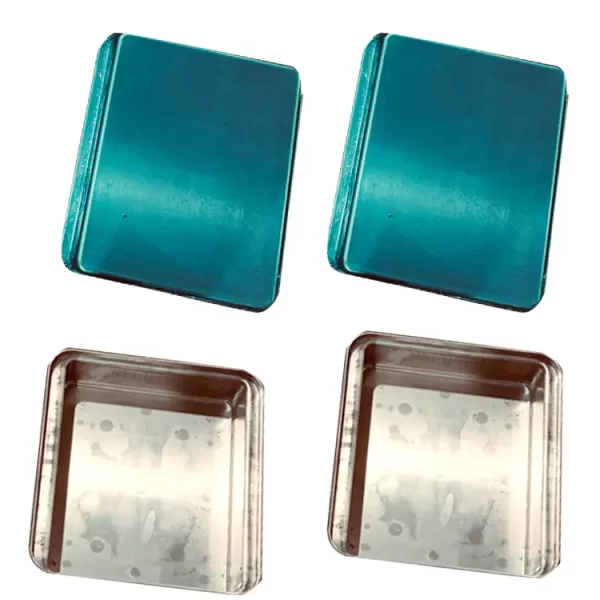

Grandshine Custom Die Casting Mold & Stamping Mold

Why Grandshine is your professional custom product development supplier?

●20 years experience in custom mold and products development.

●Engineer teams’ technology were from Japanese mold and Taiwan mold Technology.

●From Product design to molding to production one-stop product development service.

●ISO9001:2015 and ISO14004:2015 Quality System and BSCI social audit certificate.

●Plastic,Silicone,Metal alloy,PDB FPC 4 different production in same system to ensure perfect assembly.

Specification

|

Model: |

Custom Die Casting Mold & Stamping Mold |

|

Material: |

Carbon steel, SPCC, SGCC, Stainless steel, Aluminum, Brass, Copper, etc. |

|

Processing: |

Laser Cutting, Precision Stamping, Bending, CNC Punching, Threading, Riveting, Drilling, Welding etc |

|

Surface Treatment: |

Brushing, Polishing, Anodizing, Powder Coating, Plating, Silkscreen printing, Sandblast, etc |

|

Tolerance: |

+/-0.2mm, 100% QC quality inspection before delivery, can provide quality inspection form |

|

Logo: |

Silk print, Laser marking. |

|

Size: |

Accept custom size. |

|

Color: |

White, black,silver, red, grey, Pantone and RAL, etc |

|

Drawing format: |

DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI,PDF, JPG, Draft. |

|

Sample |

Available |

|

Mold Time: |

15-20 days |

Here Are All Information You Care About Product Development

Take a look at products description below. If you still have questions,feel free to contact us email or whatsapp.

What Grandshine Can Do For You To Develop A New Product?

When you have new products design idea, you can send us your design file or our industrial design company will help you fullfill your idea into real products. For a new product development, Grandshine provides custom product services include: Product design,industrial design, mechanical design,product structure design,mold design,fast prototype,mold manufacture,mass production and final assembly.

Grandshine appoints a project manager or engineer to each individual project. The project manager is in charge of the project from start to finish. All project management team communicate in good English and are qualified. You never need to spend many times in supply chain management by communicating with different suppliers. Grandshine is your golden supplier of new product development.

Grandshine Custom Alloy Die Casting Mold Advantages and Benefits

Product Design For Your New Product Development

Grandshine provide product design solution from concept and idea to the complete product design. This includes Industrial Design,mechanical product design and structure design and electronic design.We create effective Product experiences through design thinking base on market demand. The design includes complete structural design, Stack-up design, Tolerance analysis, and material selection, DFMEA, DFM and DFA. One of the Design Integrity’s most valuable tools in new product design is the failure modes and effects analysis (FMEA). Our product design company zealously trying to uncover potential weaknesses or failure points and correcting them as early in the project as possible.

When you looking for designer to draw your new products,you can externalize your design’s ideas and thoughts in simple line-work or hand-drawn or digital sketch to communicate the design direction. Any new ideas developed will be incorporated in during industry design process. These design undergo refining stages and ideas be illustrated into 3D drawing or render presentations. We will invite you involve in every design process and finish final design result and product’s details. Grandshine offers Industrial Design Solutions of high and unmatched standards. Our ID solutions offer features which enhances functions, value and appearance of products.

Free Mold Design To Save Your Mold Design Engineer Cost

As we know, mold design engineer cost is expensive in America or Europe. But we can provide you free mold design to help you save your mold engineer cost.

Grandshine is a professional molding manufacturer. We ensure that one high quality molds or precise metal alloy parts start from a great mold design and mold precision.Grandshine’s Engineers pay more attention to die casting mold construction, size to ensure the best design solution be used for molds. We use 2D & 3D software to proceed the CAD / CAM processes, we need the 3D drawings for making the mold according to the structure of plastic parts and the 2D drawings to specify the dimensions & tolerances of the molded parts.We will work with you closely and provide optimized proposal such as mold steel, mold design,products structures,raw materials selection etc.

You can provide ProE Part File; STEP;IGES file format for the 3D part file; and DWG; DXF or SLDDRW file formats for the 2D drawings.All molds are carefully designed to maximize its mold’s life and easy to maintenance, all molds are made economically and functionality to meet your expectations.

Fast Prototype Before Moulding To Ensure Your New Product Design Perfectly

Before Moulding,both you and Grandshine need to ensure new products feasibility. Therefore, we will make fast prototype to analyze products’ appearance and structure. We provide 3D print prototype,soft mold prototype,CNC prototype to meet different product’s material.

Fast Prototype is iterated more than once after refining or fine-tuning the various design aspects. Our in-house prototyping abilities are a great asset in getting the required product aspects inspected and refined prior to approval. You can ensure your new product design is perfect before mass production.

Moulding Manufacture To Ensure Your New Product Quality

Only one good quality metal alloy mold can manufacture top quality products. You may have experience that your products quality can’t be improved no matter how do you try. The main issue is you are not professional in a good quality mold manufacture or you select the cheap mold supplier instead of professional mold factory.

Currently we have 50 experienced mold makers engineers, most of the them have 15years experience in plastic molding industry,most of them learn from Japanese mold factory and Taiwan mold factory.We are able to provide 60-80 sets of molds per month.We introduce latest technology continuously and equipped the most advanced mold manufacturing facilities, we have full in-house mold manufacturing, die cast molding, metal stamp molding,painting, assembly capacity, our equipment includes but not limited to: 6 sets of CNC, precision 0.005mm; 16 sets of EDM, 9 sets of slow wire cut, 25 sets injection molding machines range from 120 Ton to 800Ton.We have experience to manufacture plastic part for Tesla car.

If you want to manufacture good quality products,good mold is the first step and Grandshine is your best choice of product development and mold manufacturer.

Mass Production To Help You Finish One Shop Purchase

After mold assembly, our engineer team will to mold trial on die casting machine. We will produce T1 samples to evaluate mold status and products’ details. If T1 is not good enough, we will do mold tiny modify to make sure mold in perfect condition before shipment. Then we will make T2 samples to your reviews.After T2 or T3 samples been confirmed by you, we can finish whole mold project and start to mass production.

Your OEM and ODM molds for metal alloy products is warmly welcomed.

Final Assembly To Offer Final Complete Products For Your Market Directly

Maybe you face challenge of product assembly locally because of higher labor cost or not standard product assembly line.Grandshine provides fully assembled and semi-finished products and plastic alloy mould maker for you. We assemble according to the technical specifications no matter the product batch size or product category. All products should be passed drop test,wear-resistant test,Salt Spray Test and Rohs test in our lab. We are equipped with 4 standard assembly line and dust-free workshop, with a group of highly skilled quality testing and assembly staff. We provide a one-stop service for you from R & D, production, assembly, quality testing, with timely delivery, excellent quality and services, which have earned us numerous awards and recognition.

If you are looking for a mold factory with assembly line or just looking for assembly line factory to assemble your products, Grandshine can provide you professional products assembly service and can be your supply chain management company.

Optimize Logistic Management To Help You Save Shipping Cost:

Grandshine cooperate well with many shipping company,our shipping agent can provide you optimize logistic solution with competitive price. They can provide you door to door logistic service, you just need to stay at home and wait for your order arrive. Welcome to contact us if you need a optimize logistic solution.

Equipment List:

| Metall Alloy Punching Machine List | ||||

| Name of Manufacturing Machine | Manufacturer | Origin | Machine Specification | Qty |

| Bending Machine | / | China | AMADA | 2 |

| CNC punching Machine | / | China | AMADA | 1 |

| Hydraulic Machine | / | China | DSB 500T | 15 |

| Punching Machine | / | China | AMADA 45T | 3 |

| Punching Machine | / | China | AMADA 110T | 1 |

| Punching Machine | / | China | AMADA GOT | 1 |

| Punching Machine | / | China | AMADA 80T | 1 |

| Milling Machine | / | China | Taiaing | 3 |

| Grinding Machine | / | China | M618S | 2 |

| Drilling Machine | / | China | Xihu | 4 |

| Lather Machine | / | China | CDS 6132 | 1 |

Place Your Order Now!

With over 500K pieces accessories being produced by Grandshine each month ,you can rely upon us to meet urgent requirements too. You also can custom your own design products in our factory.

Our products are good and reliable quality as well. All has passed CE Rohs Reach FCC certificate. We also offer a warranty for a period of 1 year to build your faith in our company. You also can get after-sales service solution within 24hrs when you face any issues. So, get your hands upon to have your brand products now!

Grandshine is a trusted company with premium quality management system. Grandshine factory has passed ISO9001:2015 quality management system and ISO14001:2015 environment management system and BSCI social ethic factory audit. Whether it is the quality standard or customer services , we have always lived up to customers’ expectation.

While shipping, your order is safely packed and delivered with perfect care. We have experienced order operator to keep you update of shipping information and provide best tariff & shipping cost door to door shipping services. You just need to stay at home to wait for your order arrival and enjoy your life or travel. Our products have been showcased in events around the world. No matter in USA ,Canada,Spain,Ghana etc, you will spot these products in our local warehouse everywhere!

Email kaiwin@grashine.com or Whatsapp +86 13823302586 or Call us now to get your own brand products order manufacture.Welcome to visit our factory in China and Vietnam whenever you come. Cheers for our cooperation.