Why Grandshine Is Your Professional Over Mold Products Supplier?

●) 20 years experience in custom mold and new products development.

●) Engineer teams’ technology were from Japanese mold and Taiwan mold Technology.

●) From Product design to molding to production one-stop product development service.

●) ISO9001:2015 and ISO14004:2015 Quality System and BSCI social audit certificate.

●) You can custom your own products from Grandshine

Here Are All Information You Care About Product Development

Take a look at products description below. If you still have questions,feel free to contact us email or whatsapp.

Grandshine Provide Full Range Of New Product Development Process

1)MECHANICAL DESIGN

We provide product design solution from concept and idea to the complete product design. This includes Industrial Design,mechanical product design and structure design.We create effective Product experiences through design thinking base on market demand. The design includes complete structural design, Stack-up design, Tolerance analysis, and material selection, DFMEA, DFM and DFA. One of the Design Integrity’s most valuable tools in new product design is the failure modes and effects analysis (FMEA). Our produt design company zealously trying to uncover potential weaknesses or failure points and correcting them as early in the project as possible.

2)Structural Design

Structural Design provides the ability to anticipate possible outcomes of the Design and take the suitable decisions to prevent failures. Wide range of Design and analysis activities are carried out including Concept Sketching, 2D Design & Drafting, 3D Modelling, Prototyping, Performance, Safety , tolerance and thickness analyses are also carried out. Prototypes and 3D models are examined using the best of lin

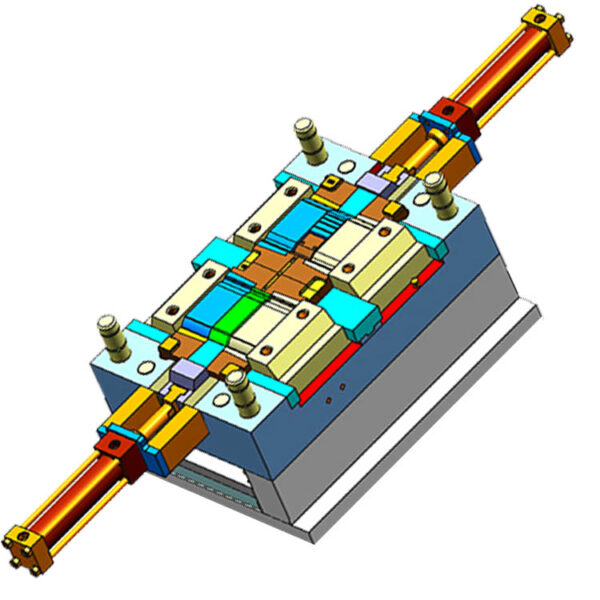

3)Mould Design

Grandshine is a professional plastic mould suppliers. We ensure that one high quality molds or precise plastic parts start from a great mold design and mold precision.Grandshine’s Engineers pay more attention to plastic mold construction, injection gates, runners, cooling channels and mechanisms to ensure the best design solution be used for molds. We use 2D & 3D software to proceed the CAD / CAM processes, we need the 3D drawings for making the mold according to the structure of plastic parts and the 2D drawings to specify the dimensions & tolerances of the molded parts.We work with customers closely and provide optimized proposal such as mold steel, mold design,products structures,raw materials selection etc. You can provide ProE Part File; STEP; IGES file format for the 3D part file; and DWG; DXF or SLDDRW file formats for the 2D drawings.All molds are carefully designed to maximize its mold’s life and easy to maintenance, all molds are made economically and functionality to meet customer’s expectations.

4)Electronic Design

Gifted with years experience in electronic design, our electornic design team enjoys an extensive knowledge in many fields of the electronics technology.such as consumer electronic design, retail scanning and payment electronic,smart home application electronic,wifi internet device electronic etc. Utilizing suitable tools and latest equipment and techniques, our highly experienced professionals cover all aspects of PCB engineering to provide our clients with physical layout that matches exactly with the schematic design.

5)Fast Prototype

A prototype is the last stage before finalizing the development phase,Sometimes this step is iterated more than once after refining or fine-tuning the various design aspects. Our in-house prototype abilities are a great asset in getting the required product aspects inspected and refined prior to approval.

6)Moulding Manufacture

Only one good quality plastic injection mold can manufacture top quality products. You may have experience that your products quality can’t be improved no matter how do you try. The main issue is you are not professional in a good quality mold manufacture or you select the cheap mold supplier instead of professional mold factory.

We are Chinese top 10 experts in custom mold field in China. All our molding products have perfect performance and will not shutt-off and the joint of the two materials is very smooth.Our products were applied in United Airline service device,Samsung retail device and Square payment devices etc.

If you want to manufacture good quality products,good mold is the first step and Grandshine is your best choice of product development and mold manufacturer.

7)Mass Production

After mold assembly, our engineer team will to mold trial on injection machine. We will produce T1 samples to evaluate mold status and products’ details. If T1 is not good enough, we will do mold tiny modify to make sure mold in perfect condition before shipment. Then we will make T2 samples to your reviews.After T2 or T3 samples been confirmed by you, we can finish whole mold project and start to mass production.

Grandshine has 25 sets plastic injection machine capacity from 120T to 800T, which can produce small size plastic parts to big size auto plastic parts. When you manufacture mold and product mass production in same factory, you can avoid many issues during mold running period,you can get final products smoothly from Grandshine and save many cost.

8)Assembly line

Grandshine provides fully assembled and semi-finished products and plastic mould maker for our customers. We can test and assemble according to the technical specifications no matter the product batch size or product category. We are equipped with standard assembly line and dust-free workshop, with a group of highly skilled quality testing and assembly staff. We provide a one-stop service for our customers from R & D, production, assembly, quality testing, with timely delivery, excellent quality and services, which have earned us numerous awards and recommends.

9 )Tips For New Product development

1. Application situation

Where there is a demand, there is a market. New products are developed to meet the needs of specific situations. Addressing the needs of the occasion is not only the selling point of your product, it is the essence of the product. Of course, this also limits the consumption target group, market positioning and scale. Because only certain people can appear in certain situations. Role fitting and playing. As with products, so with people. Therefore, in the early stage of product development, we should study these occasions as much as possible, identify the needs of the occasions, design corresponding functions and applications, and develop humanized and convenient solutions.

For example, the ipad case has been over-hyped by the market, so that all the accessories related to ipad have sold well in the market, but the whole mobile phone accessories industry has been in the red sea, and the market has fallen into a price war. Finally, on the basis of ipad protective case, we add mount stand device, which can increase the standing function of ipad, and can also be applied in various industrial occasions, which solves the problems of ipad in industrial application at a time, and gives new life to the original old products. The occasion is right, the person is right, find the occasion for you, in order to find your blue ocean.

2. Industry standard

Different industries of products, design standards and acceptance standards are not the same, such as industrial applications of products pay attention to strong and reliable, appearance and shape is not so harsh. Consumer application products require much higher appearance, fashionable appearance design, volume and size are often accurate to mm.

Industrial equipment, consumer appliances, and electronic equipment, all have their different industry standards, for safety, life, reliability requirements are also different, so before the development of new products, we must understand the product application industry, in order to design a good product.

3. Experimental design

Most product failures are due to inadequate experimental design. In the early stage, we can design UE/UX through user experience to continuously improve the functional features of the product. We can verify the reliability and stability of the product through accelerated aging test ALT and life test.

We must not blindly carry out empirical and subjective judgment, we must make vague questions specific, specific questions need to be written, and written questions need data. Fortunately, CAE software is relatively convenient now, which greatly reduces the cost of experimental design.

This is also the biggest difference between finished product Assembly and parts development. Parts, that is, parts, rely on molds, and other things are secondary, but finished product assembly is FATP,Final Assembly, Testing and Packing, so testing is the center of finished product. Never three clap surprise case, one clap head line, two clap chest, three clap buttocks scattered.

4. Technical change management

Technological change is essential in new product development. However, it should be noted that when the technology changes, it needs to be carefully evaluated, verified, data and analysis. At the same time to evaluate the impact of the associated parts, there are some changes, the parts that need to be changed. Also for the parts before the change, whether to cut in or running change, need to be carefully evaluated.

All changes must be managed in a closed loop. For design, it is not just updating the drawing, for manufacturing, it is not just producing new parts, the most important thing is to verify the results and solve problems. Of course, document management in the process is also crucial. When you change, you have to know why, how and when.

5.Product Development Process

A good development process is a great way to get more done with less. We cannot rely on individual ability to develop products, we should rely on a good system. This is the FTTA model that I’ve been trying to talk about, which is From Tell to ask. At present, well-known R & D process systems include Agile,APQP,PDM,PLM, etc. These systems are very easy to use, but the most important thing is to have practical operation. For example, some companies have a sound system, but it is just not practical, a lot of documents are to deal with, it is a pity.

In reality, due to the pressure of product launch, many necessary evaluation and verification links are avoided in the development process, and then only another mistake can be used to correct the initial mistake, which is often more than worth the loss. A lot of things are like this, only at the beginning to do it right, is the most time and effort saving. Einstein said the same thing. we cannot solve our problems with the same thinking we used when we created them.

6.Technical data

Complete technical development data, including PRD, drawings, BOM, test acceptance standards, process documents and so on. The drawing and test plan are the source of all technical data, and the test plan is the basis for verifying the success of the product.

Drawing standardization is very important. Complete drawings not only include graphics, dimensions and technical requirements, but also conform to GD/T specifications.

Test plan is the core content to ensure product quality, product design and manufacturing itself should be centered around the product test plan, quality is not produced, is designed, and proved through testing.

7.New product standards

With this kind of product, you just follow the basic development and design principles, and while there is no innovation, there is generally no mistake.

So how do you innovate? That’s what I always suggest to developers is that they have to have the ability to search for patents. You can search for relevant products or structures on the market and learn to imitate and optimize them. Innovation has to pay a price, what price, is that you have to do experiment and test the price. Innovation without verification is also wrong.

8.Learn from others

Before developing and designing a product, it is necessary to study and analyze the market of the product to select its essence and discard its dross. Only by understanding the current situation of the industry can we develop products that keep up with The Times. Only by understanding the current technology can we go ahead of others.

9.Be open-minded

In the company of three, there must be a teacher. As a developer, you should be open to different voices. Especially for the suggestions and complaints of other departments, we should face up to, learn to criticize and self-criticize. Mold, injection molding, assembly, quality, testing and other frontline personnel’s opinions are the most intuitive, we should dare to accept others’ suggestions and criticism, in order to constantly improve ourselves, develop good products.

How To Manage Suppliers Effectively Determines Success Of New Product Development.

Supplier management in the new product development stage needs to consider three aspects:

1. Should we set up a special supply management department to support new product development?

2. How to select suppliers and communicate the company’s expectations for suppliers?

3. How to enable suppliers to meet the requirements of new product development?

1、Set up a dedicated supply management department

For new product development, common positions include product manager and buyer. The product manager is primarily responsible for realizing the needs of the engineering staff at a strategic level and selecting the right suppliers. Another major task of this role is to communicate internally and coordinate supplier selection between the product development and production phases. This is because suppliers suitable for new product development are not the best choice for the production stage. For example, the scale of these suppliers is usually small, the response speed is fast, but the management system and quality system are not as perfect as that of large suppliers. It is best for the company that the suppliers selected in the new product development phase also become the suppliers in the production phase, thus reducing the problems caused by switching suppliers. Purchasers are mainly responsible for order processing, timely understanding of designers’ intentions, placing orders, tracking orders and reminders.

Grandshine has a comprehensive new product development process, and we can respond to new product development in 48 hours. In addition, grandshine’s factory has passed ISO9001 and ISO14001 management system certification, and we can provide a full range of product development services from product development to product production.

2、Make a list of suppliers

The simplest and most effective way to do this is to create a list of suppliers. If you want to add a supplier, it must go through strict approval. With the vendor selected, the next step is to explicitly deliver expectations. May wish to sign a memorandum, indicating the company’s overall delivery, quality, orders, tracking, reminders, receipt and inspection of the specific requirements. For example, the delivery time can specify the approximate production cycle of products with different levels of complexity, and how many percentage points shorter the delivery cycle than the mass production stage. Such memorandums do not have to be legally binding, but setting expectations in writing is conducive to the supplier’s correct understanding.

Grandshine appoints a project manager or engineer to each individual project. The project manager is in charge of the project from start to finish. All project management team communicate in good English and are qualified engineers. Grandshine has finished more than 6000 new products development successfully from 2009.

3、Conduct supplier assessment

A classic theory of management: You get what you count.

The company should develop a special system for statistics. For example, on-time delivery, if the goal is 95% on-time delivery, then you have to have a system in place to measure that and inform suppliers regularly. If the target is not met, either change the supplier or help the supplier improve its capability. When managing suppliers, it is also important to determine if they have the systems and processes in place to support new product development. For example, whether specialized quotation staff, order processing personnel, customer service personnel and engineering and technical personnel, as well as specialized production equipment, must require suppliers to have clear responsibilities. Without system support, supplier promises are only lip service, so there is often no guarantee of implementation. For suppliers, the trust should be verified at the same time, and the assessment must be carried out through meetings or on-site visits, etc., to ensure that the supplier’s commitment is supported by a complete set of systems and processes, which is also the value of professional supply management personnel. Grandshine has a professional product development team and engineering team, we can provide you with a professional and on time solution for your product development. Welcome to visit our factory and develop new products together. Contact us at kaiwin@grashine.com