How does Plastic Injection Molding Service Benefit You?

Here is how the plastic injection molding benefits the manufacturer of the plastic part:

High Productivity

You can get prompt manufacturing of plastic parts through the plastic injection molding service. That’s because of its fast production rate and capability of producing a high volume of plastic parts in one cycle. As the mold can have numerous cavities, the higher the cavities, the higher the parts you can get in a single molding cycle. In addition, thousands of parts can be obtained through injection molding before the tooling needs to be maintained.

High Repeatability

Injection molding can lead to the production of numerous parts having constant form and dimensions. The parts manufactured through various molding cycles are ensured to be identical, which benefits you when product consistency is essential.

Low Labor Costs

The injection molding process involves less manufacturing cost as it is a highly automated process. The machine performs most steps of the process run by an operator, therefore reducing the manual labor.

Low Scrap Rates

The injection molding results in the generation of less scrap in comparison to traditional manufacturing processes and CNC machining. After the injection molding process, the heating and remolding of excessive plastic from the runners, gates, and sprue can be done if a recyclable thermoplastic material is utilized.

Design Flexibility

Plastic injection molding allows designers to integrate undercuts, complex geometries, and multiple features into a single part. This results in reducing the need for assembly. In addition, it enables the incorporation of threads, inserts, and other components directly into the mold.

Scalability

The plastic injection molding process is scalable. That means manufacturers can adjust production quantities easily to meet the customers’ demands without necessary retooling or setup costs.

What Are the Applications of Plastic Injection Molding Service?

Plastic injection molding services are applicable in numerous industries, and here’s how:

Medical Industry

Plastic is commonly utilized in the medical industry. Resins are non-toxic, lightweight, and don’t cost much. In addition, resins can be recycled and reused. They are used to manufacture catheters, dispensers, syringes, tubing, and other appliances.

Electronics

Plastic injection molding comes as an ideal solution to solve the problems of the electronic industry. Components such as wires, batteries, sensors, and circuit boards must be housed in sturdy, lightweight, and non-conductive housings to ensure their and the user’s safety.

Agriculture Industry

The plastic products used in the agriculture industry should possess strong and durable properties and be capable of resisting UV light and chemicals. Engineered plastic parts are utilized in feeders, water sprinklers, fencing, tools, conveyor belts, and many other aspects.

Consumer Products

You use plastic in everyday routine work. From game controllers, headphones, and toys to home appliances and kitchen gadgets, plastic components having different properties are utilized.

Aerospace Industry

The materials of plastic injection molding for the aerospace industry are selected depending on the stringent aerospace standards, such as fire resistance, less smoke emissions, and conformity with different regulations. Plastics are crucial in improving aircraft functionality, enhancing passenger safety and comfort, and reducing weight. However, they are not commonly used for essential structure components.

Why Choose Grandshine for Plastic Injection Molding Service?

The quality of raw materials, strict quality control, and advanced technology and equipment are what make the finest production of plastic achievable. Only a supplier with competitive prices and years of experience can give you repeatable results for your production tooling needs.

Here’s why Grandshine is a perfect choice for plastic injection molding services:

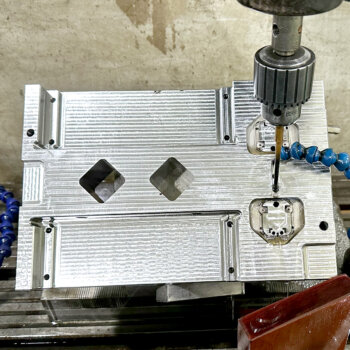

High-Quality Mold Design and Manufacturing

At Grandshine, we offer exceptional mold design and manufacturing solutions. We cover every aspect, including raw material verification, tool manufacturing, part verification, finishing, and final inspection. We ensure the custom molded parts, regardless of their complex shape, are consistent in quality through conducting in-process inspections and dimensional verification.

Advanced Technology and Equipment

Our sophisticated manufacturing technology and equipment ensure the flawless production of plastic parts consistently and in high volumes. Using our latest injection molding technology, we transform raw plastic into your expected products.

Strict Quality Control

Quality assurance at each step is not just our promise but a commitment. We encompass rigorous quality control measures from mold design to the final production stage. Consequently, we ensure that each plastic material leaving our factory meets your specifications.

In addition, Grandshine has passed ISO9001:2015, an internationally recognized standard for quality management systems. The certification is evidence of the factory’s commitment to provide services based on customer requirements and to stick to regulatory and legal requirements.

Fast Delivery Time

Your success is our foremost priority, and we prefer meeting deadlines on time. Due to our efficient production capabilities and streamlined processes, we ensure the delivery of your projects within 20 to 30 days. However, we can provide exceptional results within one week for a priority project.

Competitive Price

We prefer delivering valuable products to our clients. That said, our top-notch plastic injection molding service offers competitive pricing that gives you a strategic benefit in the market. Our experts are well aware of how to optimize production processes and reduce waste so that we can offer you the most competitive price in the industry. Our expertise in providing cost-effective solutions without compromising the quality is what makes us the best fit.

Reliability and Reputation

If you are concerned about whether our molding services are reliable, fortunately, we have already collaborated with popular customers like United Airlines, Jetblue Airline, Amtrak, and Lenovo. Moreover, we also served T-Mobile, Wiko Phone, Incipio, and Case-mate. Your success is a matter of our reputation.

Customization Capability

We work closely with you to tailor our mold design according to your unique requirements. Our goal is to bring life to your plastic product concepts with unique precision and uncompromised quality. Our experts craft every mold thoroughly so it can meet the industry’s high standards and provide the results you demand. Based on our active product development cycle, we can manufacture 80 sets of molds per month, saving your time.

Sustainability and Environmental Protection

We are dedicated to sustainability and environmental protection in every aspect of our plastic injection molding services. We prefer using environmentally friendly and recyclable thermoplastic materials. Our recycled programs ensure that excess materials and scrap are properly managed. In addition to ISO 9001:2015 certification, the factory has passed ISO 14001 environmental management standards, demonstrating that we are devoted to minimizing the environmental impact of our operations.

Quality Control at Grandshine

At Grandshine, you are in good hands. We utilize high-quality raw materials to customize injection molds so the resulting products meet or exceed your expectations and industry standards. Our robust quality control processes ensure your peace of mind and give you confidence regarding our services. The quality inspection testing starts at the beginning of your project.

We tailor our quality control measures according to your project’s individual requirements, regardless of whether you need specific testing, certifications, or custom quality protocols. Cherry on the top, we are ISO 9001: 2015 certified, which is evidence of our determined commitment to quality. This certification ensures that our quality management systems are up to the mark and continuously improved.

Why do Our Customers Trust Us?

At Grandshine, we consider that open and timely communication is the keystone of excellent customer service. In this regard, our team is here to answer your queries, give updates, and address any concerns 24/7. We won’t leave you in the dark from the initial query to project completion and even beyond.

In addition to being service providers, we help you in problem-solving. In the case of any challenges during the project, we are your trusted partners to find solutions so your project remains on track.

What’s more? We are looking forward to making our customer service better. Your feedback is valuable to us, so feel free to give us your recommendations. We employ your feedback to bring improvements to our processes and service delivery.

Contact Us Today for Plastic Injection Molding Service

Contact us today for our molding services that guarantee quality, fast delivery, and competitive prices. Join us, and let’s bring life to your vision and upgrade the future of plastic products together. Give us a call to discuss your project or email kaiwin@grashine.com, and let us bring excellent results that elevate your products above the competition.