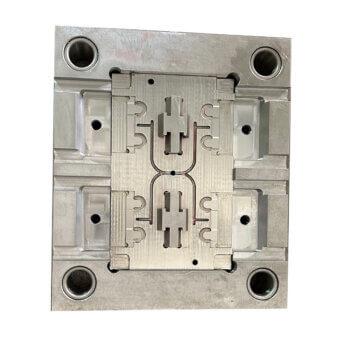

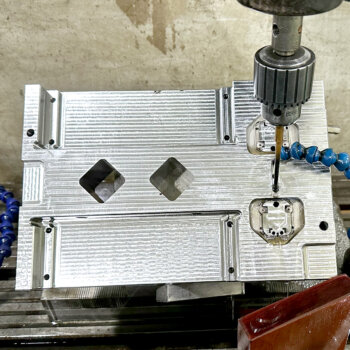

Grandshine Precision Injection Molding in China and Malaysia

Grandshine has established itself as a trusted name in precision plastic molding in China and Malaysia. Our modern facilities are based on cutting-edge technology and highly skilled professionals. From design, tooling, and molding to assembly, we provide a one-stop solution for your manufacturing requirements.

In China, our manufacturing facility is strategically located to cater to the world’s largest market. Due to our reputation for efficiency and quality, we have become the go-to choice for businesses seeking high-quality injection molded products.

In Malaysia, we have a distinct advantage that can help you save on import tariffs. Malaysia possesses favorable trade agreements and lower tariffs compared to many other countries. You can benefit from these trade agreements and access your target markets more cost-effectively by manufacturing in Malaysia.

Why Can You Get Manufacturing in Malaysia?

The strategic location and favorable trade agreements of Malaysia make it an attractive option for businesses looking to save on import tariffs.

Here’s why manufacturing in Malaysia can be a smart choice:

Strategic Geographic Location

Malaysia is located at the crossroads of major shipping routes, making it an ideal location for businesses with global supply chains. Its proximity to Southeast Asian markets and access to major international ports facilitate cost-effective distribution.

Trade Agreements

Malaysia has numerous trade agreements like the Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPPP) and the ASEAN Free Trade Area (AFTA). These agreements reduce import tariffs and result in easier market access for products manufactured in Malaysia.

Skilled Workforce

The country contains a skilled and well-educated workforce, which ensures high-quality manufacturing and product consistency.

Lower Labor Costs

Malaysia offers competitive labor costs, which aid businesses in reducing production expenses and improving cost-efficiency.

Grandshine Molding Service Industry Range

At Grandshine, we pride ourselves on our versatility and ability to serve various industries. Our capabilities and expertise cover different product categories, including:

Phone Accessories

We provide high-quality injection-molded phone accessories, including phone cases and chargers that meet with the latest trends and models.

Tablet Accessories

We provide various tablet accessory solutions, including stands, mounts, and cases, designed to meet the needs of tablet users.

Medical Device Parts

Precision and quality are paramount in medical device manufacturing. We excel in producing components that meet the strict standards of the medical industry.

Consumer Electronics

Our expertise extends to the manufacturing of different consumer electronic components, ensuring that your products meet high-quality standards.

Home Appliances

We provide reliable, durable, and efficient injection-molded parts, from kitchen appliances to home automation devices.

Auto Parts

We manufacture a wide range of auto parts, including exterior and interior components, ensuring reliability and safety in the automotive industry.

Final Thoughts

Grandshine Precision Injection Molding is your trusted partner in China and Malaysia and offers manufacturing solutions that meet the highest quality standards. Our extensive industry coverage ensures we can provide the right solution to your needs. Choose Grandshine for reliability, precision, and cost-effectiveness in injection molding.