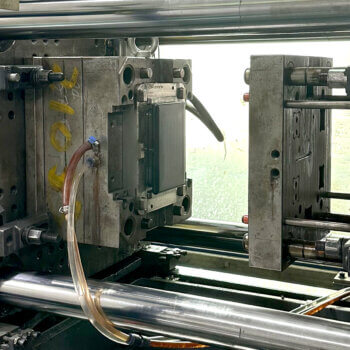

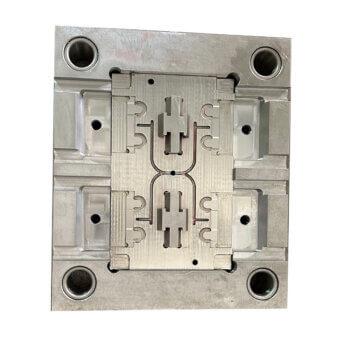

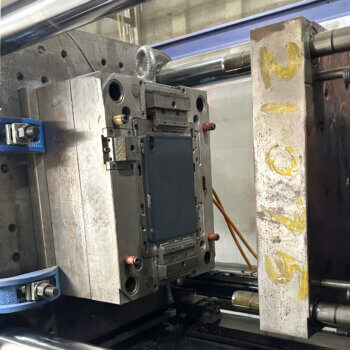

Injection Mold Tooling

Plastic Injection MoldingPlastic Injection Molding is a common process for making plastic parts and plastic products. The process works by injecting heated plastic material into a mold, allowing it to cool and harden in the mold, ultimately forming the desired part or product. Plastic injection molding are used in various industries, including automotive, electronics, consumer goods, medical devices, industrial components, furniture accessories, communication devices, packaging, sports and outdoor equipment. |

Injection Moulding ManufacturersThe key to ensuring high quality products is to choose high quality precision molds for production. In the process of looking for injection mold manufacturers, you will be faced with a variety of prices provided by different factories, there are cheap mold quotes, there are expensive mold quotes, which makes the choice quite difficult. |

|

|

Insert MoldingGrandshine is one of insert molding manufacturer, we provide custom insert molding to combines plastic and metal materials, allowing metal inserts in plastic parts. This insert molding technologies integrates the characteristics of both plastic and metal materials, providing diverse possibilities for applications. Materials used in Insert Molding injection include: Insert Molding products offers the combined advantages of enhanced product strength, streamlined assembly processes, material savings, and increased design flexibility by seamlessly integrating threaded inserts for plastic injection molding. |

Molding Over MoldingGrandshine has extensive experience in over molding, our products are widely used by major airlines such as United Airlines in the United States and Lufthansa in Germany. Our co-molded products exhibit strong adhesion, successfully passing rigorous tests including a 10-meter(3ft) drop test and a tension violence test. These overmolded parts feature a 4-grade resistance to yellowing and oxidation. The injection overmolding products from our company showcase a seamless fusion of two materials, imperceptible to both touch and the naked eye. Our over molding technology is on par with the precision molding techniques of Japan and Germany. Grandshine offer PC+TPU overmolding injection molding, PC+Silicone plastic overmolding, PC+TPE co injection moulding, TPU+TPE overmolds and other insert overmolding. Grandshine is your best choice of plastic mould company. |

|

|

Plastic Mold TexturePlastic mold texture is the process of creating a texture or pattern on the surface of the mold so that the surface of the final plastic product has a specific texture or pattern. This process is mainly through the use of a special surface treatment such as a scrub tool, chemical treatment or polishing tool in the mold or the addition of a texture board to produce the desired appearance and touch effect on the plastic product. The texture choice of plastic mold is leather texture, wood texture, hemp texture, mesh texture, wave texture, grass texture, pearlescent texture, the most common mold texture is mt11010 matte texture and smooth polishing. You can specify a specific texture number or give us a sample of the plastic mold texture you want, so that we can develop the texture you want for the plastic mold. |

Plastic Mold ManufacturerIf you consistently encounter issues such as delayed mold delivery, poor mold quality, lack of precision in molds, short mold lifespan, coarse parting lines in plastic components, high product defect rates, contamination, uneven color, fragility of injection-molded parts, or the inclusion of recycled materials in your products, it may be time to seek out a new plastic mold manufacturer. Grandshine is a professional plastic mold manufacturer with 20 years of experience in injection molding and silicone molding. We are committed to delivering high-quality molds and plastic products. Our promise includes using entirely new steel for mold production and fresh raw materials for product manufacturing. Each project has a dedicated project management team overseeing every step from product design and mold production to large-scale manufacturing, all adhering to the ISO9001:2015 international quality management standard. This ensures that every product we produce for you is of high precision and quality. Furthermore, with offices in the United States and Singapore, we provide excellent local after-sales service. If you are in need of a new plastic mold factory, Grandshine is undoubtedly your top choice. |

Plastic Injection Mold Manufacture Video |

Advantages Of Oem Manufacturing |

| 500K Mold Life Grandshine-developed molds have a lifespan of 300,000 to 500,000 new product development life cycle, ensuring long-term stability in product planning and development. We are ISO9001 certified, and our new product process have received ROHS, CE, FCC, and REACH certifications, guaranteeing high-quality and compliant products for you. |

Qiuck Lead Time Grandshine always stands from your perspective, offering high-quality injection mold making and product manufacturing within your budget. Additionally, we provide a rapid molding manufacturing turnaround of 15-25 days, enabling you to swiftly introduce new products or meet market demands. |

Accurate Design Grandshine assigns dedicated project engineers for each project to ensure comprehensive project management. Before plastic injection mold tooling, we provide clients with 3D and 2D drawings for confirmation and offer quick prototyping for validation. This process ensures that the mold design aligns with the client’s product requirements and specifications, meeting all functional, aesthetic, and performance criteria. |

Low MOQ To facilitate customer market expansion and ease inventory constraints, Grandshine offers production support with a flexible minimum order quantity (MOQ) ranging from 500 to 1000. This approach allows customers to confidently enter the market with minimal inventory pressures. Reach out to Grandshine now to kickstart the development of your new products! |

Grandshine is a professional injection moulding product manufacturer, providing you with precision injection, plastic injection mold tooling, plastic injection overmolding, plastic injection molding inserts, abs plastic molding, medical plastic injection molding, automative injection molding, PC plastic die mould and other injection molding services. We usually use high temperature and chemical corrosion resistant S136 steel as the mold material, after 52 degrees of mold and hard heat treatment, to ensure that your mold has 300K-500K mold life.

We focus on high quality product quality standards and fast production cycles, usually able to develop a complete set of molds for you in 15-25 days and put into mass production. If you need a flexible minimum order quantity (MOQ) and want to choose an ISO9001, ISO14001 and BSCI certified plastic injection molding manufacturer, Grandshine is the best choice for you.