Why Grandshine is your professional Insert moulding products supplier?

●) 20 years experience in custom plastic injection mold and products development.

●) Engineer teams’ technology were from Japanese mold and Taiwan mold Technology.

●) From Product design to molding to production one-stop product development service.

●) ISO9001:2015 and ISO14004:2015 Quality System and BSCI social audit certificate.

●) You can custom your own products from Grandshine.

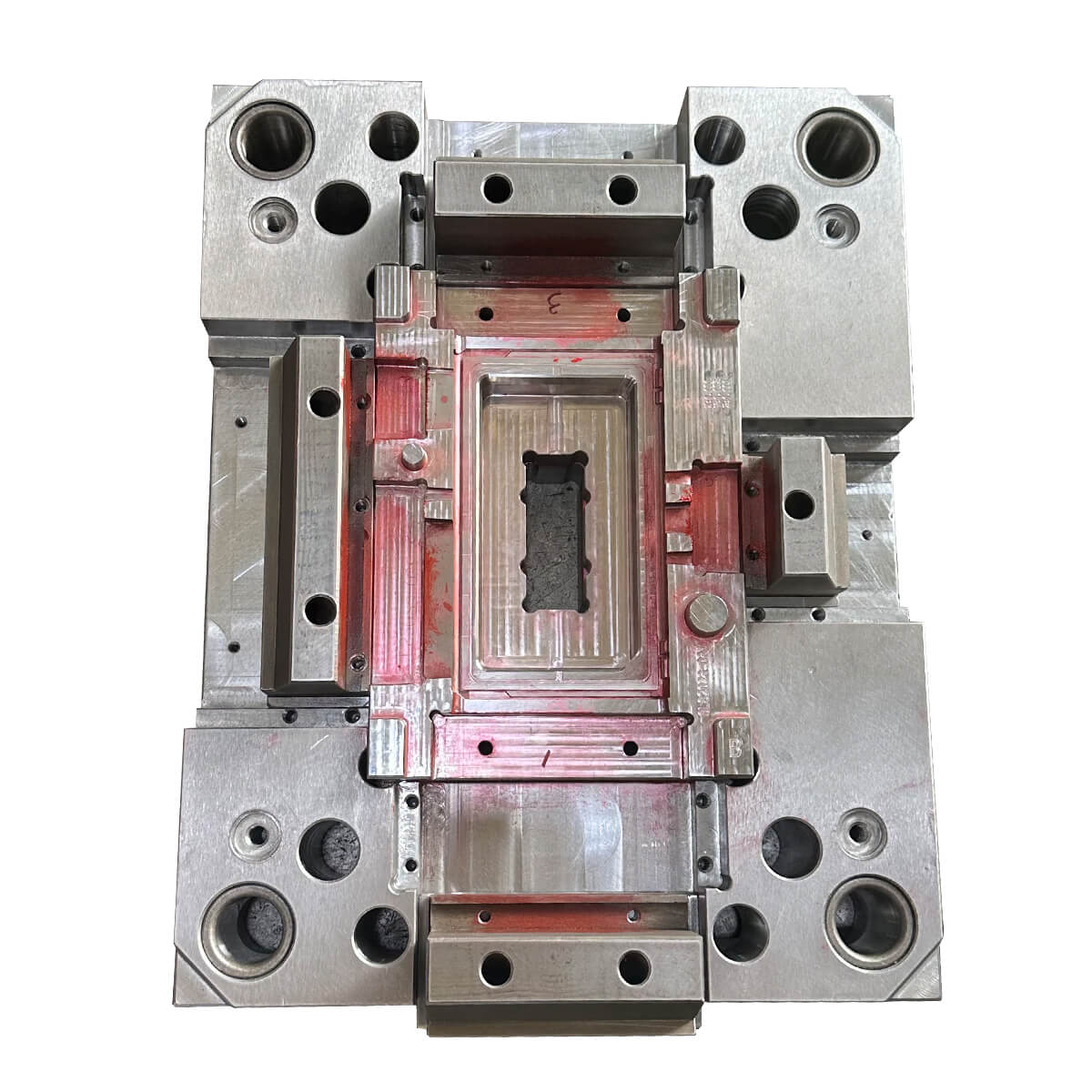

Specification:

|

Mold Base: |

LKM, HASCO, DME or your requirement |

|

Mold Material: |

P20, H136, 718, 1.2344, 1.2738 and so on |

|

Standard: |

HASCO, DME, MISUMI, PUNCH and so on |

|

Product Material: |

PC/ABS, ABS,TPU,TPE,TPR, PA66, POM or other. |

|

Runner : |

Cold/Hot Runner |

|

Gate Type: |

Side gate, Sub gate, Pin point gate, Edge gate etc |

|

Mould Weight: |

50kg-15Ton |

|

Injection Machine Type: |

80-1500Ton |

|

Standard for Product: |

Appearance for graining MT(Mold Tech), YS, HN Series The Way of Color Contrast for Plastic RAL PANTONE |

|

Certificated: |

ISO 9001:2015 Certificated |

Here Are All Information You Care About Product Development

Take a look at products description below. If you still have questions,feel free to contact us email or whatsapp.

What Is The Purpose Of Making Inserts In Injection Molds?

Insert molding is the process of molding thermoplastic material around a preformed assembly (recessed) to create a part containing multiple materials. Inserts are usually metal parts used to enhance the mechanical properties of plastic parts. Inserts are placed into a plastic mold, and thermoplastic is injected into the mold to form the part. The use of molded embedded plugins eliminates the need for secondary installation of the plugins, which reduces costs, as compared to installing the plugins into the plastic parts during the post-forming process.

Insert Molding Process

Three embedding methods for nuts

There are three ways to insert the nut into the plastic:

1) Hot melt nuts

Hot melt embedding is the most common, the most common embedding way, generally with hot melt machine and manual electric soldering iron buried nails;

2) Injection molded nut for insert

Injection molding generally has strict requirements on the hole size of the nut pillar, and the hole size is controlled within 0.05mm. Because the product is fixed with Moding Pin and placed in the injection molding mold, the hole size of the nut should be controlled by the size of the PIN pin of the injection molding machine.

3) Ultrasonic nuts

Ultrasonic embedded nut is a kind of ultrasonic vibration, so that the friction between the nut and the product surface and internal molecules and the interface temperature increases, when the temperature reaches the softening temperature of the product itself, the nut is embedded in the rubber parts, when the vibration stops, the product at the same time under a certain pressure cooling and setting.

Insert Injection Molding Benefits

1)The combination of plastic’s formability, elasticity and metal’s rigidity, strength and heat resistance can be solidly made into complex and sophisticated metal-plastic integrated products; Reduce the size and weight of the product;

2)Using the combination of the insulation of plastic and the conductivity of metal, the molding products can meet the basic function of electrical products; It can also meet some special requirements, such as magnetic conductivity, wear resistance and fastening, etc.

3)Adding metal inserts into plastic can improve the strength of plastic parts;

4)Injection molding of insert increases the flexibility of product design, providing new possibilities for the combination of plastic and metal and other parts;

5)Avoid the secondary processes such as hot melting, welding and riveting to shorten the assembly time and cost;

6)Inserts are not limited to metal, but also cloth, paper, wire, plastic, glass, wood, coil, electrical parts and plastic parts, etc

7)For the rigid forming products and the flexor elastic forming products on the rubber sealing gasket, the complex operation of arranging the seal can be saved after the product is made by injection molding on the matrix, which makes the automatic combination of the last process easier;

8)Because it is the combination of molten plastic and metal inserts, compared with the pressure molding method, metal inserts can be designed more narrow clearance, higher product reliability; Easier to pass tests such as vibration;

9)Appropriate plastics and forming conditions are selected, that is, products prone to breakage (such as glass, coils, and electrical parts), which can be sealed and fixed by plastics

10)Select the appropriate mold structure, the insert can also be completely sealed into the plastic.

11) Combination of vertical injection molding machine and manipulator, insert product whole column device, etc., insert molding engineering can mostly realize automatic production.

Insert Injection Molding Disadvantage

1)The placement of inserts often complicates the mold structure, prolongs the injection molding cycle, increases the manufacturing cost, and increases the difficulty of automatic production;

2)The coefficient of thermal expansion of the insert and plastic is inconsistent, which is easy to make the final product produce internal stress, resulting in product rupture; This point is particularly obvious in the injection molding of nut inserts.

3)Because the thermal expansion coefficient of the insert and plastic is inconsistent, resulting in deformation of the product;

4)Inserts (especially nut inserts) often need to be preheated or dried to reduce the internal stress;

5)The insert must be well fixed in the mold, otherwise it is easy to shift or deformation under the impact of the solution;

6)Once the injection molding of the insert produces defective products, such as bad injection molding, missing insert, poor position, etc., it will cause the whole product scrap, with huge cost;

7) Injection molding of insert is not conducive to product recycling and scrap.

Whats Products Need Insert Molding Process.

Insert injection molding is widely used in automotive, medical, electronic products and connectors and other industries.

Insert Mold Design Instruction

1)Selection of insert materials. Copper, aluminum, steel, hard dissimilar plastic parts, ceramics, glass and plastics can be used as insert materials, among which, brass is not rust, corrosion resistance, easy to process and price is moderate, is commonly used in insert materials.

2)Shape of insert. Adopts circular or axisymmetric shape, does not allow the existence of sharp or acute Angle, uniform contraction and prevent the production of local stress, even stress concentration phenomenon;

3)The insert itself needs to consider its own DFM. Metal inserts are made by cutting or stamping, so the shape of the inserts must have good processing technology.

4)In order to facilitate placement and positioning in the mold, the extension part of the insert (that is, the part placed in the mold) should be designed to be cylindrical, because the mold processing round holes is the easiest;

5)the insert should have a sealed boss and other structures to prevent overflow during injection molding;

6)In order to avoid the appearance and strength of the plastic bottom which is too thin and appears corrugated shrinkage, the minimum distance between the bottom of the embedded part and the plastic wall should be taken

7)The spacing between the insert and the side wall of the product should not be too small to ensure that the mold has a certain strength;

8)When the insert is set in the boss, in order to ensure the stability of the insert and the strength of the plastic matrix, the insert should be extended to the bottom of the boss (to ensure the minimum bottom thickness), and the insert head is rounded;

9)Small cylindrical inserts can be inserted in the plastic matrix with intermediate grooves or surface rhomboid knurling structure, and the knurling groove depth is 1~2mm;

10)Plate and sheet inserts can be fixed by hole and window fixing, but thin inserts (thickness less than 0.5mm) should be fixed by cutting or bending;

11)The rod-shaped insert can be fixed by flattening, punching, bending and splitting the head, or by flattening the middle part of the round rod;

12)Tubular stamping inserts, which can be processed into bulge bulge during stamping to enhance the fastening force;

13) In the connector, the fastness of the terminal insert in plastic is a priority for each product design engineer to consider. The commonly used methods are as follows, which can greatly enhance the fastness of the terminal in plastic;

Plastic terminal drilling;

Shaped terminal in plastic;

Plastic terminal bending;

Plastic terminals increase roughness, bump points;

Increase the thickness of the plastic wall.

Nut inserts are one of the most common inserts. The nut inserts and the corresponding plastic parts of the pillar must be correctly designed, otherwise there will be insufficient pulling force, pillar fracture and other quality problems.

Attention In Design And Selection Of Automatic Insert Molding Products

1、Metal insertmolding is easy to produce uneven shrinkage, we should do extreme testing of insert molding products shape and dimensional accuracy.

2、The metal insert is easy to deform and shift during the injection process, so the mold composition and the design of the mold shape which is easy to keep the metal insert should be fully considered. For products whose insert shape cannot be changed, test beforehand.

3、When the metal inserts are arranged and separated, the contact between the metal inserts and the vibration ball of the inserts will cause slight damage to the surface of the inserts, and affect the quality of the products. The permissible limit of quality should be confirmed in advance.

4、Measure the serrated, warpage, material thickness difference, diameter difference and thickness difference caused by gold processing of the insert due to stamping. On this basis, the design of the automatic device and the design of the mold structure.

5、The predictable matters that restrict the mold construction, such as the location of the mold gate and the forming cycle, should be solved in advance as far as possible or have corresponding improvement countermeasures.

6、Check whether the metal inserts need to be preheated or dried. The purpose is to ensure the quality of products and the stability of molding.

7、Various detection devices set in the mold are used to ensure the stability of the molding action under the influence of environmental conditions such as heat, force and vibration of the mold. It should be confirmed whether to use them.

8、In order to avoid metal inserts, forming pieces of the fine accumulation in the mold cavity, can be assembled air blowing device.

9、Due to the high investment price of system equipment, the production capacity of equipment operation should be fully considered before use. When using automated machines, it is necessary to ensure that the product can be continuously produced over several years without formal renewal

10、When general automation machines are used, it is necessary to confirm how many combinations of multi-variety and low-batch inserts are produced. If the overall cannot guarantee mass production, the recovery of the fixed assets of each product is difficult. In this case, a part of the device needs to be replaced, which can be adapted to the requirements of variety renewal within a certain range.

11、Insert molding rate, production and molding cost conditions, the precision of metal inserts, the shape of inserts, whether the mold is conducive to insert molding and molding product shape and other factors and technical ingenuity.

12、The effective combination of injection machine, mold and automatic device and how to play the function in a short time is the key to determine the automatic insert molding system. It is recommended that you consult with manufacturers with considerable achievements and experience.

Free Mold Design To Save Your Mold Design Engineer Cost

As we know, mold design engineer cost is expensive in America or Europe. But we can provide you free mold design to help you save your mold engineer cost.

Grandshine is a professional plastic mold manufacturer. We ensure that one high quality molds or precise plastic parts start from a great mold design and mold precision.Grandshine’s Engineers pay more attention to plastic mold construction, injection gates, runners, cooling channels and mechanisms to ensure the best design solution be used for molds. We use 2D & 3D software to proceed the CAD / CAM processes, we need the 3D drawings for making the mold according to the structure of plastic parts and the 2D drawings to specify the dimensions & tolerances of the molded parts.We will work with you closely and provide optimized proposal such as mold steel, mold design,products structures,raw materials selection etc.

You can provide ProE Part File; STEP;IGES file format for the 3D part file; and DWG; DXF or SLDDRW file formats for the 2D drawings.All molds are carefully designed to maximize its mold’s life and easy to maintenance, all molds are made economically and functionality to meet your expectations.

Fast Prototype Before Moulding To Ensure Your New Product Design Perfectly

Before Moulding,both you and Grandshine need to ensure new products feasibility. Therefore, we will make fast prototype to analyse products’ appearance and structure. We provide 3D print prototype,soft mold prototype,CNC prototype to meet different product’s material.

Fast Prototype is iterated more than once after refining or fine-tuning the various design aspects. Our in-house prototyping abilities are a great asset in getting the required product aspects inspected and refined prior to approval. You can ensure your new product design is perfect before mass production.

Moulding Manufacture To Ensure Your New Product Quality

Only one good quality plastic injection mold can manufacture top quality products. You may have experience that your products quality can’t be improved no matter how do you try. The main issue is you are not professional in a good quality mold manufacture or you select the cheap mold supplier instead of professional mold factory.

Currently we have 50 experiened mold makers engineers, most of the them have 15years experience in plastic injection molding industry,most of them learn from Japanese mold factory and Taiwan mold factory.We are able to provide 60-80 sets of injection molds per month.We introduce latest technology continuously and equipped the most advanced mold manufacturing facilities, we have full in-house plastic injection mold manufacturing, injection molding, painting, assembly capacity, our equipment includes but not limited to: 6 sets of CNC, precision 0.005mm; 16 sets of EDM, 9 sets of slow wire cut, 25 sets injection molding machines range from 120 Ton to 800Ton.We have experience to manufacture plastic part for Tesla car.

We are Chinese top 10 experts in over-mold field in China. All our over-molding products have perfect performance and will not shutt-off and the joint of the two materials is very smooth.Our over-molding plastics products were applied in United Airline service device,Samsung retail device and Square payment devices etc. Over-molding is also called 2 times injection molding,it means to apply one material onto another material. Here two color pistol grip, utilizes TPU injected onto PC material.Two types material should form a bond and offer functional performance.Compared with the third-party material bonding, over-molding process makes the process faster and more cost-effective, it has been widely employed in plastic design.

If you want to manufacture good quality products,good mold is the first step and Grandshine is your best choice of product development and mold manufacturer.